- Joined

- Oct 31, 2016

- Messages

- 2,718

I have never used a welding table let alone made one. A month ago one of my neighbors who was moving set out a folding table among other things on the curb. Free for the taking. I grabbed the table, a rolling cart with drawers and a small metal can with a lid. The rolling cart now has my cut off saw sitting on it and the can is now my shop trash can. I use the lid to keep track of small parts when I am working on something.

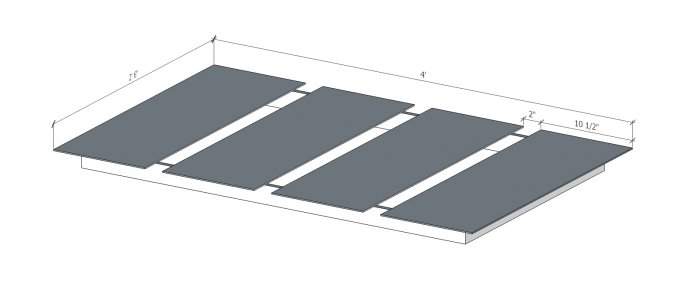

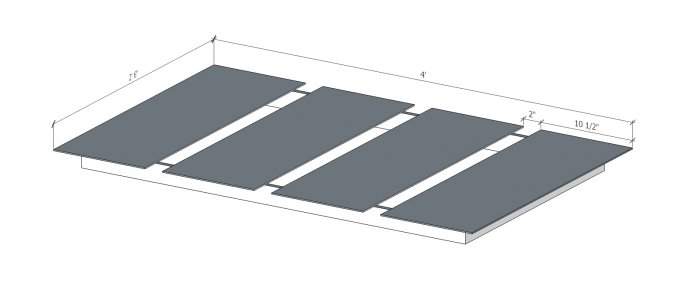

The table's 3'x8' top had some rather large holes in it and being pressed board weight a ton. Broke up the top and into the trash it went. I already have several work benches but don't have a welding table. Got to thinking that if I shortened the frame and welded some flat steel to the frame it would make a welding table. Had to go into Fresno yesterday and stopped by a manufacturing plant that sells their scrap at 50 cents per pound. Picked up a 21" x 60" x 1/8" plate to make the top. Here is my idea for the top of the table.

The top will overhang the frame by 2" all the way around. The legs which I didn't draw in will fold up so the table can be stashed somewhere when not in use. Due to the small size of my shop everything has to be able to be stored when not in use.

I have not cut the steel plate that I bought. Will this work for a welding table?

The table's 3'x8' top had some rather large holes in it and being pressed board weight a ton. Broke up the top and into the trash it went. I already have several work benches but don't have a welding table. Got to thinking that if I shortened the frame and welded some flat steel to the frame it would make a welding table. Had to go into Fresno yesterday and stopped by a manufacturing plant that sells their scrap at 50 cents per pound. Picked up a 21" x 60" x 1/8" plate to make the top. Here is my idea for the top of the table.

The top will overhang the frame by 2" all the way around. The legs which I didn't draw in will fold up so the table can be stashed somewhere when not in use. Due to the small size of my shop everything has to be able to be stored when not in use.

I have not cut the steel plate that I bought. Will this work for a welding table?