- Joined

- Feb 2, 2013

- Messages

- 3,957

I have a Powcon 300SS welder that stopped working last winter under mysterious circumstances.

the welder was sounding normal and during the middle of a pass, it quit working all together.

rather than fix it right on the spot, i took my other Powcon, a 200SM, off the shelf and use it in place of the 300SS for DC stick welding

i use my PowCon 200SM as the dedicated power supply for my FCAW (Flux Core) Rig, but it swaps out in less than 5 minutes.

I finally got a chance on Friday to repair the 300SS welder...

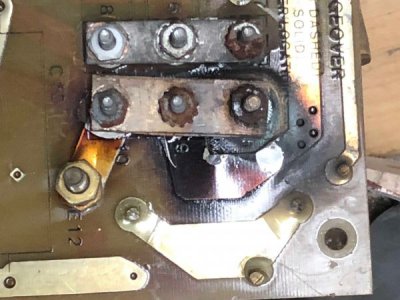

it got ugly inside....

as you can see the Capacitor PCB Board blew up.

i had sourced a new old stock PCB from a nice fellow on Ebay, it was shipped fast and packed very well, i may add.

Then the fun began,

the board is held in place with screws and more than a dozen electrical connections that need to be put back exactly where they came from,

or you could fry the new board you are trying to replace!

the PowCon part number on the Capacitor PCB Board is 100220-001, for those looking to do the same job.

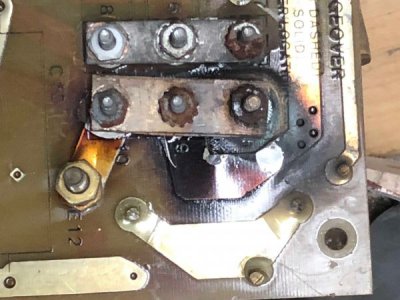

here is a picture of the 90% installed board assembly, it is wired up for 230V operation

i reassembled the unit and reinstalled the covers for the test run.

i ran some 3/32 E6011 just for giggles.

the welder performs flawlessly.

if there is interest, i'll make a video of the welder and it's capabilities.

as always thanks for looking!

the welder was sounding normal and during the middle of a pass, it quit working all together.

rather than fix it right on the spot, i took my other Powcon, a 200SM, off the shelf and use it in place of the 300SS for DC stick welding

i use my PowCon 200SM as the dedicated power supply for my FCAW (Flux Core) Rig, but it swaps out in less than 5 minutes.

I finally got a chance on Friday to repair the 300SS welder...

it got ugly inside....

as you can see the Capacitor PCB Board blew up.

i had sourced a new old stock PCB from a nice fellow on Ebay, it was shipped fast and packed very well, i may add.

Then the fun began,

the board is held in place with screws and more than a dozen electrical connections that need to be put back exactly where they came from,

or you could fry the new board you are trying to replace!

the PowCon part number on the Capacitor PCB Board is 100220-001, for those looking to do the same job.

here is a picture of the 90% installed board assembly, it is wired up for 230V operation

i reassembled the unit and reinstalled the covers for the test run.

i ran some 3/32 E6011 just for giggles.

the welder performs flawlessly.

if there is interest, i'll make a video of the welder and it's capabilities.

as always thanks for looking!