- Joined

- Jan 1, 2017

- Messages

- 31

**Updated Feb 18 2017**

Hello everyone!I wanted to create a continuation to my restoration thread for my newly acquired Zip-Cut mill. Its been a few weeks and I've been slowly tooling up and getting a feel for how it handles different cutters and materials. It's a great little machine and fits my needs perfectly but its time for some quality of life improvements.

List of improvements to come:

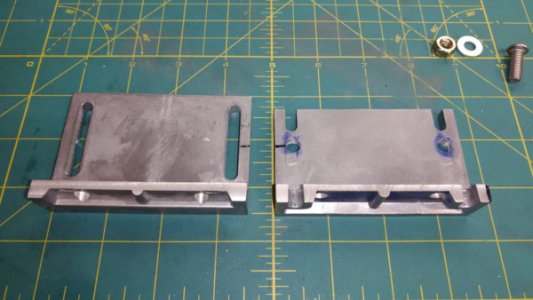

- Vise hold downs DONE

- Leveling Feet DONE

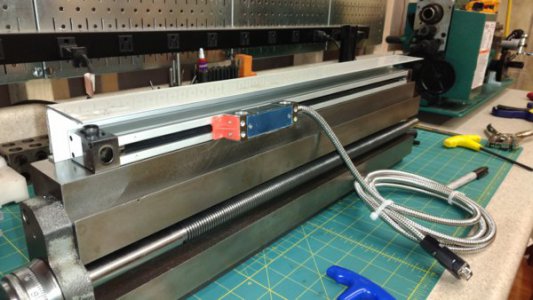

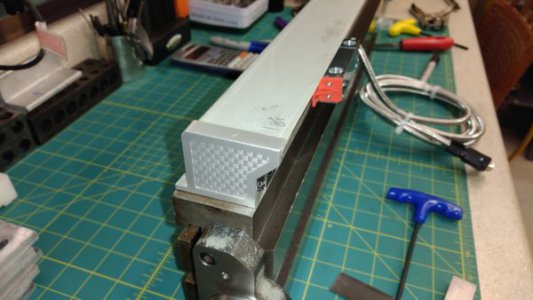

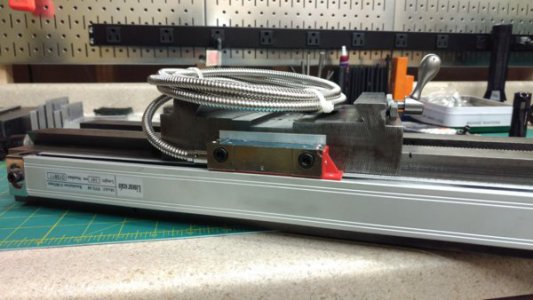

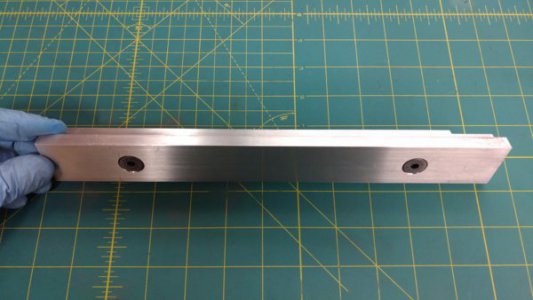

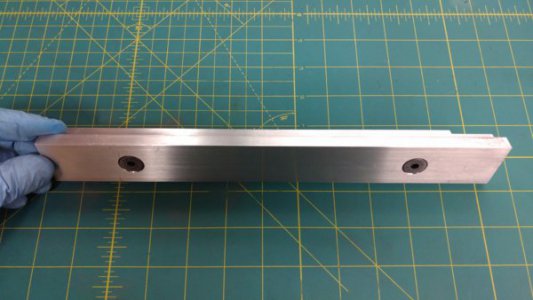

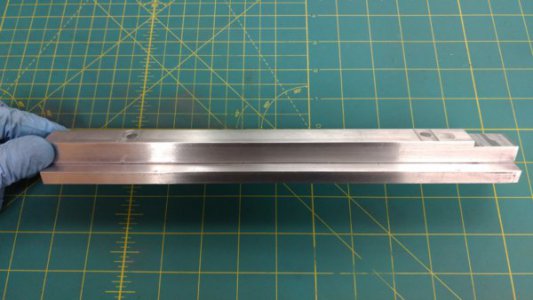

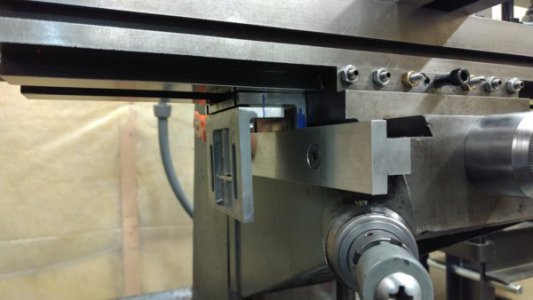

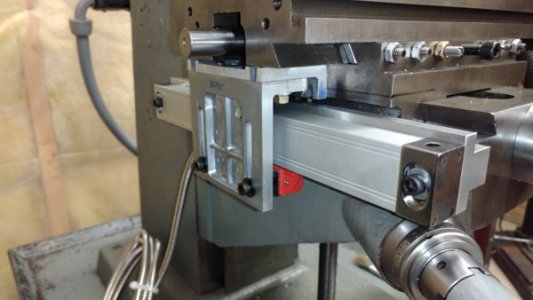

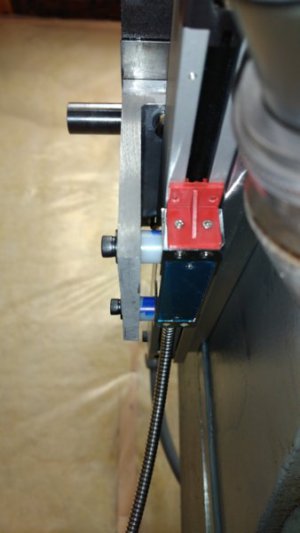

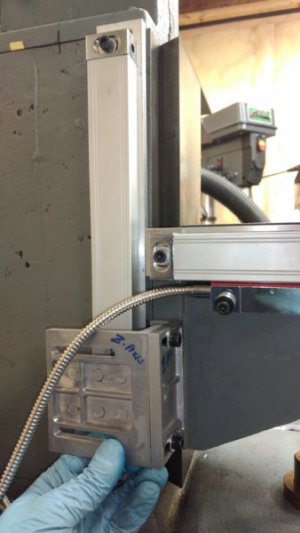

- DRO install IN PROGRESS

- Riser block (maybe incorporate a better method of tramming the head)

- Work light

- Way cover/wipers

- Metric drawbar (increased tooling options)

- Mill repower (variable DC drive)

If anyone is interested the thread can be found here: Zip-cut Vertical Mill - My First Mill + Resto (lots Of Pictures)

One of my first purchases was to pick up a quality vise. Eventually after much deliberation, I settled on a 3 inch screwless toolmakers vise. In hindsight I should have gone with a 4 inch but a 3 in will suit my needs for now and has been doing a great job. I have had very few issues with part holding other than those caused by myself (still learning).

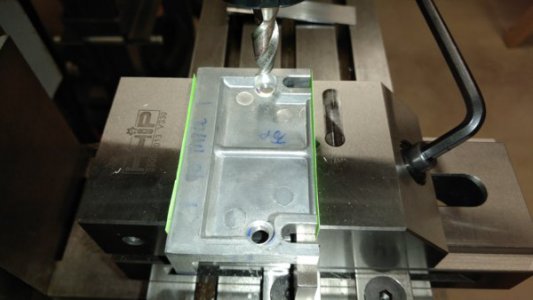

So my first project was to mill four proper hold downs for the vise. It was a fun project and a I learned how different cutters react to CRS. After the second block was finished I tried out a roughing end mill for the first time and I was blow away at how much material could be taken off with each pass. This greatly sped up the machining process. The last block was milled entirely with the end mill in the pictures. This is a really neat end mill that was given to me, that is both a rougher and finisher in one. It is solid carbide and has a copper colored coating. I was able to run this end mill at around 800 RPM and take about a 0.050" depth of cut with ease.

Now for the pictures!

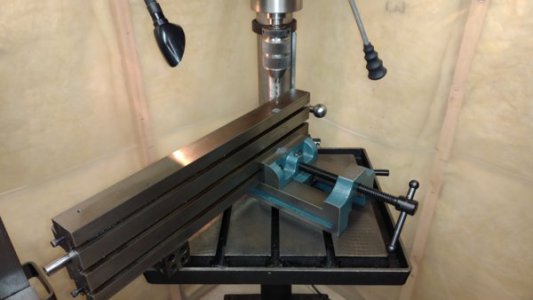

Re-tramming in the vise

Next up: DRO Install!

Last edited: