- Joined

- Feb 17, 2013

- Messages

- 4,417

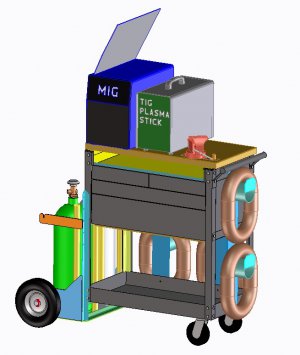

Made my very first TIG welds today! I've just bought a TIG/Stick/Plasma welder (Prime Weld CT520DP, $500 on Amazon.) I've done a little bit of MIG, almost no stick. Decided to make a welding cart for both it and my Miller MIG unit. After looking at some welding carts at HF and elsewhere, I decided I could do a little better. My design, shown below, is based on the HF 4 drawer tech cart (#64096).

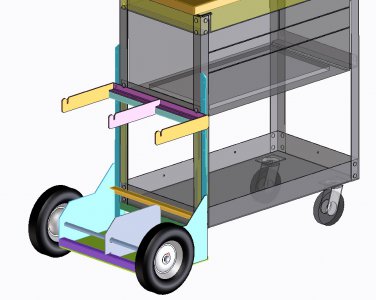

The basic idea was to remove two of the casters from the cart and add on a "trailer" of welded angle, square tubing and sheet metal, with 10" wheels, for the argon and CO2 tanks. Another mod to the basic cart is to replace the original flip top with a sturdier, permanently mounted sheet of something (plywood?), and open up the front face to make an open shelf under the welders. The original top is easy to remove, just drill out some rivets. But cutting off the front face leaves a weak piece of sheet metal to support the upper two drawers. Decided to add a stiffener to the lower front opening, using a length of 1/2"x1/2" angle. [By the way ... the onangey looking "donuts" represent where I'll be hanging various coiled-up cables.]

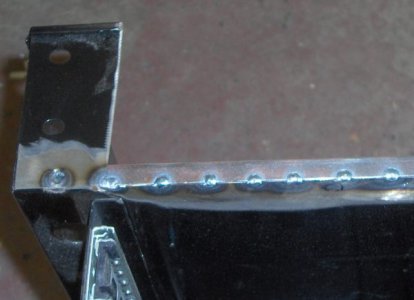

How to weld the 1/8" thick angle to the ~.040" thick sheet metal without blow-outs? I decided to use plug welds [I think that's the right term] at the ends, then stitch the sheet metal and angle together along the edge by concentrating the arc on the angle and letting the puddle expand to the sheet. The photo below shows the very first TIG welds I've ever done, on a mockup of the actual work pieces.

Plug weld #1 was no good, as I was trying to make a wide weld puddle before the heavier metal below was hot enough. Welds #2 and #3 were much better - concentrated the arc on the heavier angle below for a couple seconds, then moved sideways just enough to involve the sheet metal. The remaining welds were for practice on my edge joining technique.

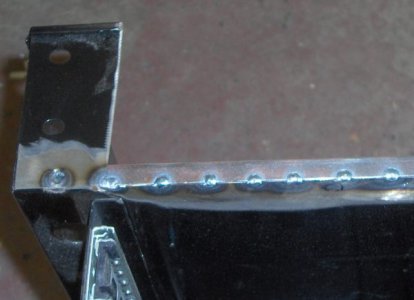

The next photos show the completed job before cleanup sanding, painting, etc.

I know I have an awful lot to learn! [Can you spell UNDERSTATEMENT?] I'll be looking for welding classes at a local community college after the first of the year. But I'm pretty well satisfied with my first effort.

The basic idea was to remove two of the casters from the cart and add on a "trailer" of welded angle, square tubing and sheet metal, with 10" wheels, for the argon and CO2 tanks. Another mod to the basic cart is to replace the original flip top with a sturdier, permanently mounted sheet of something (plywood?), and open up the front face to make an open shelf under the welders. The original top is easy to remove, just drill out some rivets. But cutting off the front face leaves a weak piece of sheet metal to support the upper two drawers. Decided to add a stiffener to the lower front opening, using a length of 1/2"x1/2" angle. [By the way ... the onangey looking "donuts" represent where I'll be hanging various coiled-up cables.]

How to weld the 1/8" thick angle to the ~.040" thick sheet metal without blow-outs? I decided to use plug welds [I think that's the right term] at the ends, then stitch the sheet metal and angle together along the edge by concentrating the arc on the angle and letting the puddle expand to the sheet. The photo below shows the very first TIG welds I've ever done, on a mockup of the actual work pieces.

Plug weld #1 was no good, as I was trying to make a wide weld puddle before the heavier metal below was hot enough. Welds #2 and #3 were much better - concentrated the arc on the heavier angle below for a couple seconds, then moved sideways just enough to involve the sheet metal. The remaining welds were for practice on my edge joining technique.

The next photos show the completed job before cleanup sanding, painting, etc.

I know I have an awful lot to learn! [Can you spell UNDERSTATEMENT?] I'll be looking for welding classes at a local community college after the first of the year. But I'm pretty well satisfied with my first effort.

Last edited: