- Joined

- Dec 13, 2020

- Messages

- 90

Hello everyone,

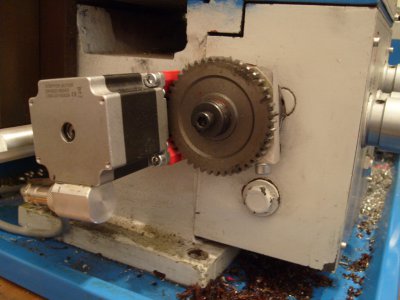

I've recently sold my old milling machine and am preparing to purchase the PM-728VT. I'm also considering adding the CNC conversion kit to it. However, I have a question for those who might have gone through this process: Can the PM-728VT still be used as a manual mill after installing the CNC conversion kit? If so, how does it perform, and are there any major compromises? I would appreciate hearing about any experiences or insights you might have on using it manually post-conversion.

Thank you in advance!

I've recently sold my old milling machine and am preparing to purchase the PM-728VT. I'm also considering adding the CNC conversion kit to it. However, I have a question for those who might have gone through this process: Can the PM-728VT still be used as a manual mill after installing the CNC conversion kit? If so, how does it perform, and are there any major compromises? I would appreciate hearing about any experiences or insights you might have on using it manually post-conversion.

Thank you in advance!