- Joined

- Dec 27, 2017

- Messages

- 340

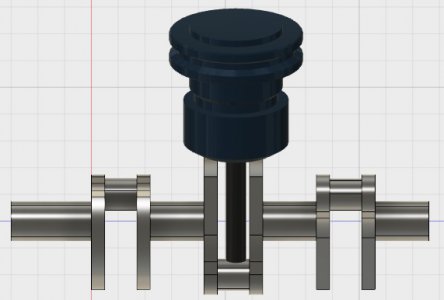

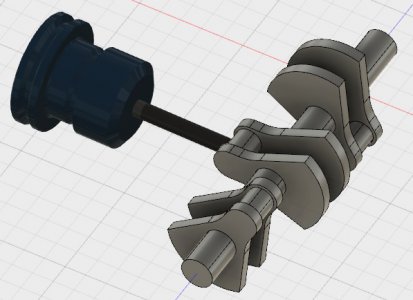

In a few weeks I plan to post pictures and also some video of a miniature crankshaft on a 4th axis setup. The most challenging area will be when I will need to do live 4th axis finishing between the counterweights so I can get to the back sides of the connecting rod journals. This will require a 3/8" end mill will a 2-1/4" stick out to reach all the way to the journal.

I thought about just using the same end mill for the whole run so I don't need to change tools. I figured that I could start with something like a .001" chipload and .050" width of cut with a .500" depth of cut. But, I am not really sure because I don't ever really mill with a stick out like that.

I plan to use a solid carbide 4 flute.

Any suggestions?

I thought about just using the same end mill for the whole run so I don't need to change tools. I figured that I could start with something like a .001" chipload and .050" width of cut with a .500" depth of cut. But, I am not really sure because I don't ever really mill with a stick out like that.

I plan to use a solid carbide 4 flute.

Any suggestions?