- Joined

- Nov 24, 2013

- Messages

- 268

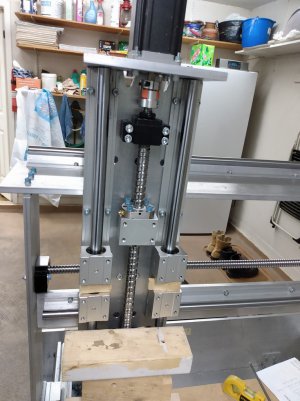

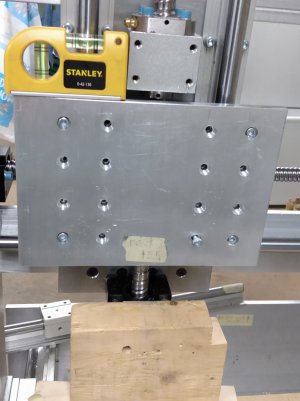

The attached pictures shows the Z axis plate which will support the water cooled spindle plate. There are 16 M5 SHCS 1/2" long. I just wonder if a lock washer will serve any purpose. In any case the spindle bracket on top of these screws will prevent them from moving.

For information this is for a 3×4 feet table top mill I build all in aluminum flat bar/plate, with 4 stepper motors and a VFD controlled water cooled spindle.

Thanks

For information this is for a 3×4 feet table top mill I build all in aluminum flat bar/plate, with 4 stepper motors and a VFD controlled water cooled spindle.

Thanks