I noticed that the outboard end of my spindle had the same M50x1.5 thread as an ER40 nut, which made me wonder if I could use an ER40 nut instead of a spider, as a self-indicating outboard stock support.

I used some 1 7/8" CRS stock and made an adapter to hold the ER40 collet inside the end of the tailstock. Because the thread doesn't run to the end of the spindle, this has less clamping range than a standard ER40, but it's good enough for most cases. And when it isn't, it's not hard to go back to the real spider.

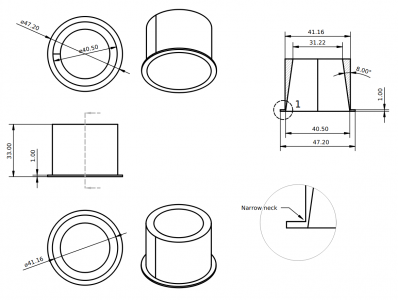

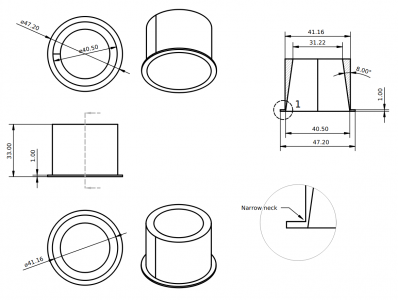

I freestyled this, measuring against nut and lathe as I went, but I reverse-engineered it afterward and made a drawing. (Sorry, as an amateur my drawings are very amateur.) All dimensions in mm because I do everything I can in metric.

That neck has to be very narrow (about ⅓mm), and the brim thin, for the nut to engage the threads that aren't very close to the end.

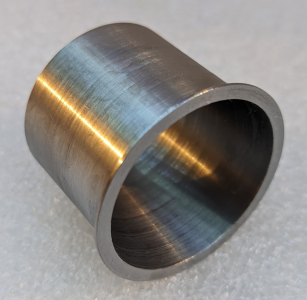

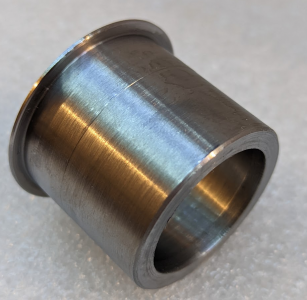

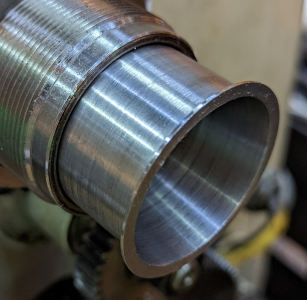

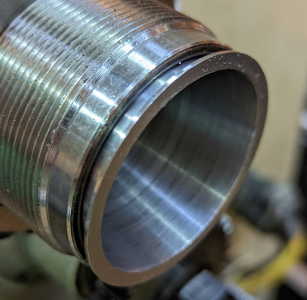

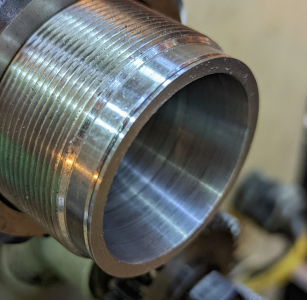

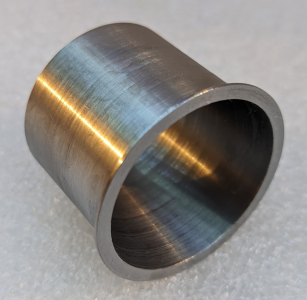

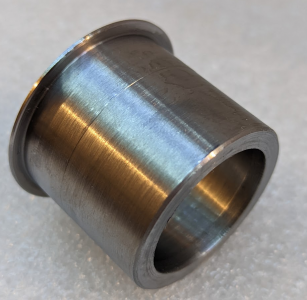

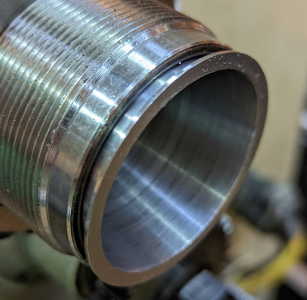

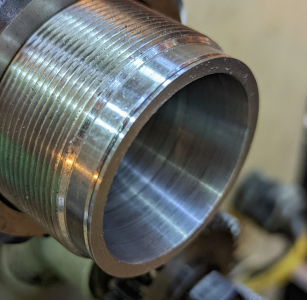

Here are some more photos:

That line about a third of a way from the brim is real and not a photographic artifact; there's clearly a slight taper inside the spindle, so I ended up with the inside end a thou narrower in diameter. That's a one thou step.

Here's the outboard end with no spider.

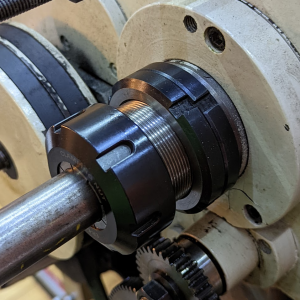

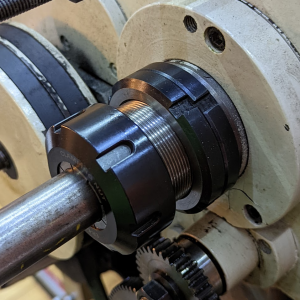

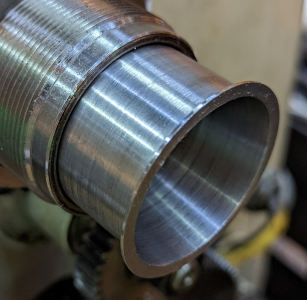

Inserting the collar into the spindle end:

With a nut and collet:

I used some 1 7/8" CRS stock and made an adapter to hold the ER40 collet inside the end of the tailstock. Because the thread doesn't run to the end of the spindle, this has less clamping range than a standard ER40, but it's good enough for most cases. And when it isn't, it's not hard to go back to the real spider.

I freestyled this, measuring against nut and lathe as I went, but I reverse-engineered it afterward and made a drawing. (Sorry, as an amateur my drawings are very amateur.) All dimensions in mm because I do everything I can in metric.

That neck has to be very narrow (about ⅓mm), and the brim thin, for the nut to engage the threads that aren't very close to the end.

Here are some more photos:

That line about a third of a way from the brim is real and not a photographic artifact; there's clearly a slight taper inside the spindle, so I ended up with the inside end a thou narrower in diameter. That's a one thou step.

Here's the outboard end with no spider.

Inserting the collar into the spindle end:

With a nut and collet:

Last edited: