-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using a watchmaker’s lathe to make a gear

- Thread starter Janderso

- Start date

That dividing head probably cost him ten grand.

The lathe itself can be had fairly cheaply, but he has made new parts for quite a lot of it.

I'm not sure the collets on my Peerless lathe are quite as precise as his, but the way he crossed out the wheel was elegant and relatively easy. The next step for him would be to file and polish chamfers on the spokes, but that's easy for me to say.

I use my lathe mostly for making new arbors or modifying current arbors with new pins. And for making bushings. Pins and plate holes are Wear Item Number 1 on clocks (those holes would usually be jeweled on watches, so only the pins would need work and then only rarely).

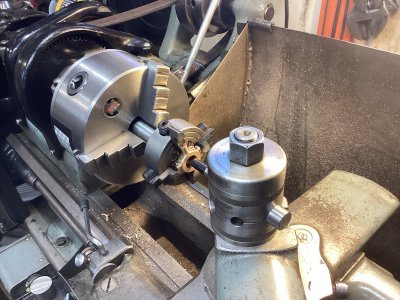

And Doug Gray generously passed along his unfinished Boley lathe project to me. It remains unfinished, but I am reconstructing a headstock for it at present. here it is with a carbide graver locked into the toolpost of the cross slide. It uses the same collets as the Peerless, but I need a locknut for the spindle which is missing on this headstock. That's sort-of a low-priority ongoing search at present.

I'm used to working small with this setup. Here's the work desk in its new home, still unorganized. Note the 20x microscope.

But cutting watch-sized wheels? That's the next level. Maybe the next two or three levels. I describe myself as a repair dilettante. I'm not even qualified to make effective repairs on watches, let alone actually make watches.

Rick "who can fix most clocks if they aren't too far gone" Denney

The lathe itself can be had fairly cheaply, but he has made new parts for quite a lot of it.

I'm not sure the collets on my Peerless lathe are quite as precise as his, but the way he crossed out the wheel was elegant and relatively easy. The next step for him would be to file and polish chamfers on the spokes, but that's easy for me to say.

I use my lathe mostly for making new arbors or modifying current arbors with new pins. And for making bushings. Pins and plate holes are Wear Item Number 1 on clocks (those holes would usually be jeweled on watches, so only the pins would need work and then only rarely).

And Doug Gray generously passed along his unfinished Boley lathe project to me. It remains unfinished, but I am reconstructing a headstock for it at present. here it is with a carbide graver locked into the toolpost of the cross slide. It uses the same collets as the Peerless, but I need a locknut for the spindle which is missing on this headstock. That's sort-of a low-priority ongoing search at present.

I'm used to working small with this setup. Here's the work desk in its new home, still unorganized. Note the 20x microscope.

But cutting watch-sized wheels? That's the next level. Maybe the next two or three levels. I describe myself as a repair dilettante. I'm not even qualified to make effective repairs on watches, let alone actually make watches.

Rick "who can fix most clocks if they aren't too far gone" Denney

- Joined

- Aug 5, 2015

- Messages

- 295

Rick,

Nice seeing another clock repairman talking about watchmaker lathes. I enjoy working on my own small clock collection. I like using my watchmaker lathe for pivot polishing and such.

Nice seeing another clock repairman talking about watchmaker lathes. I enjoy working on my own small clock collection. I like using my watchmaker lathe for pivot polishing and such.

- Joined

- Mar 3, 2020

- Messages

- 743

I was using my 2-1/4” 4 jaw yesterday machining an eccentric big end for a small engine.

I use the 3 & 4 jaw chucks from my Unimat DB200 often on my lathe, mill & RT.

I made #2 & #3 draw bar mandrels , & the straight mandrel I use with the 5” 3 jaw on my SB9.

they come very in handy on tiny parts.

I use the 3 & 4 jaw chucks from my Unimat DB200 often on my lathe, mill & RT.

I made #2 & #3 draw bar mandrels , & the straight mandrel I use with the 5” 3 jaw on my SB9.

they come very in handy on tiny parts.