- Joined

- Oct 31, 2016

- Messages

- 2,720

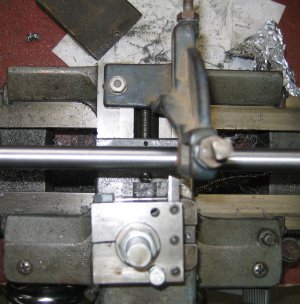

For the first time this week I had to use a follower rest. On my craftsman lathe the follower rest is at the tailstock side of the cross slide whereas the tool bit is at the headstock side of the cross slide. There is roughly 2 1/2" distance between the two. I think that this creates a bend in the work. That would defeat the purpose of the follower rest. In watching some videos the consensus seemed to be that you want the tool bit just in front of the follower rest. I could do that with my lantern tool post or by swiveling the tool holder 180 degrees. But then the closest you could get the tool bit to the headstock end of the work would be a little over 2 1/2 inches. I need some guidance on using a follower rest.

This brings up another turning between centers question. At the tailstock end you can take cuts all the way to the end of the work. Yet at the headstuck end you can't take cuts all the way to the end of the work because of the lathe dog. Do you swap the work end for end to turn the portion that was blocked by the lathe dog? And then do you swap end for end again so that the final pass is the same for both ends?

I ask this question because the action mandrel I just finished making has to be turned between centers when used. Took me forever to make this.

This brings up another turning between centers question. At the tailstock end you can take cuts all the way to the end of the work. Yet at the headstuck end you can't take cuts all the way to the end of the work because of the lathe dog. Do you swap the work end for end to turn the portion that was blocked by the lathe dog? And then do you swap end for end again so that the final pass is the same for both ends?

I ask this question because the action mandrel I just finished making has to be turned between centers when used. Took me forever to make this.