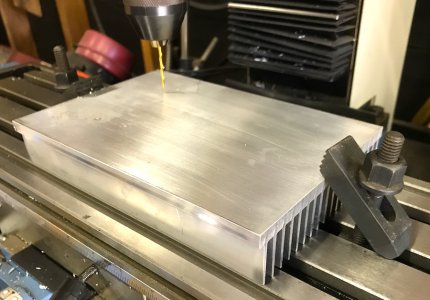

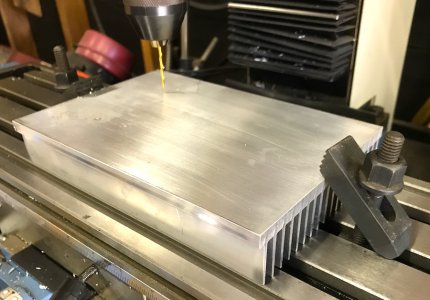

Today I needed to drill some fairly precise holes in an aluminum heatsink about 5" x 8" x 1 3/8", using my LMS 5550 mill. If I put the workpiece in the one vise I have that's large enough it wouldn't have had sufficient Y-axis travel, so I figured I'd clamp it to the table. I have a pretty standard clamping kit (LMS #1144).

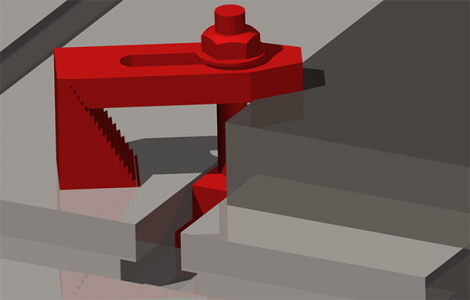

I didn't see a quick way to position the holddowns horizontally at the height of the top of the workpiece, so being short on time I just positioned them at an angle:

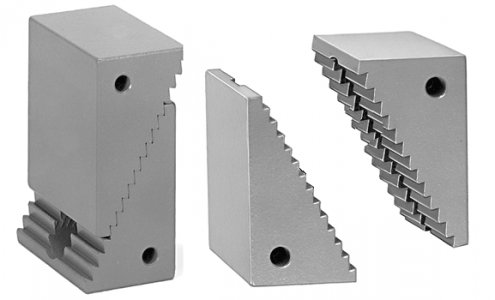

I'd intended for the top corner of the workpiece to catch in one of the stairstep pockets on the holddown, but I can see from the photo it didn't end up this way.

So long story short, this worked well enough for this purpose. But I figure there must be a better way to do this. Any suggestions?

I didn't see a quick way to position the holddowns horizontally at the height of the top of the workpiece, so being short on time I just positioned them at an angle:

I'd intended for the top corner of the workpiece to catch in one of the stairstep pockets on the holddown, but I can see from the photo it didn't end up this way.

So long story short, this worked well enough for this purpose. But I figure there must be a better way to do this. Any suggestions?