- Joined

- Nov 9, 2015

- Messages

- 429

I bought this Delta 5 speed 1/3 HP drill press 25 years ago. It worked OK in the wood shop, but the quill had become loose in the bore, plus the machine was under powered for drilling metal. Delta model 11-990:

A year ago I bought a vintage floor model Craftsman drill press to replace the worn out Delta. So the question was, what to do with the old Delta?

I searched Craig's List and found this complete, but rusted and seized King drill press. I bought it for the table lift mechanism to adapt to the Craftsman.

So now I was left with the old Delta and a rusted, seized King without a table lift.

I was able to free the quill on the King, and to my surprise found it to be very tight in the bore, even when fully extended.

I started thinking about grafting the King head onto the Delta column. Then adapting the King table to the Delta lifting mechanism.

First we made two adapter rings to allow the larger bore King head to fit onto the smaller diameter Delta column.

Then we made an adapter plate to affix the King table to the Delta lifting mechanism.

Then we put all the parts together to check feasibility of this Frankenpress. Everything seemed a go. TIR of a chucked-up end mill was less than 0.002, with virtually zero quill wobble at full extension.

Then a final clean-up.

And in its final resting place.

This leaves me with the Delta quill/spindle assembly. I am thinking of changing out the bearings and making a tool post grinder from it.

A year ago I bought a vintage floor model Craftsman drill press to replace the worn out Delta. So the question was, what to do with the old Delta?

I searched Craig's List and found this complete, but rusted and seized King drill press. I bought it for the table lift mechanism to adapt to the Craftsman.

So now I was left with the old Delta and a rusted, seized King without a table lift.

I was able to free the quill on the King, and to my surprise found it to be very tight in the bore, even when fully extended.

I started thinking about grafting the King head onto the Delta column. Then adapting the King table to the Delta lifting mechanism.

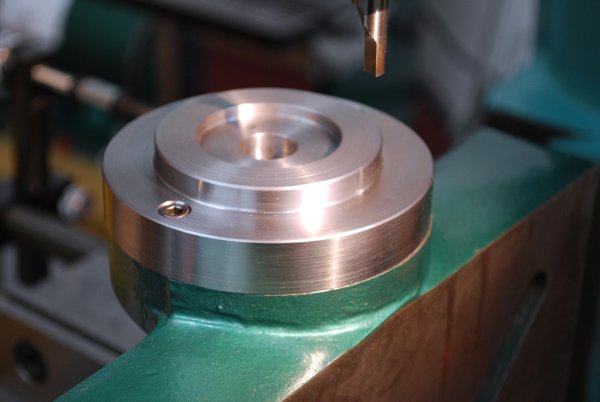

First we made two adapter rings to allow the larger bore King head to fit onto the smaller diameter Delta column.

Then we made an adapter plate to affix the King table to the Delta lifting mechanism.

Then we put all the parts together to check feasibility of this Frankenpress. Everything seemed a go. TIR of a chucked-up end mill was less than 0.002, with virtually zero quill wobble at full extension.

Then a final clean-up.

And in its final resting place.

This leaves me with the Delta quill/spindle assembly. I am thinking of changing out the bearings and making a tool post grinder from it.

Last edited: