- Joined

- Feb 2, 2013

- Messages

- 3,962

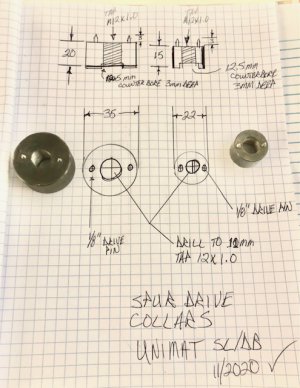

I was considering a woodturning project for the Unimat SL1000.

In preparation i constructed 2, spur drive centers.

they were loosely copied from the OEM style, i did not posses .

i saw the driver in an accessories section of the manual

i started off with 25mm 1215 steel and turned it down to 23.5mm diameter, drilled to 11mm and tapped M12x1.0

i chamfered the stick out, partially parted, and chamfered the other end before parting off the threaded bushing to 15mm long

i repeated the process with a piece of 38mm 1215, it was reduced to 35mm but this time i increased the length to 20mm.

the difference being that i knurled the 35mm section.

after the turning and deburring they were fixed in the vice of the BP

they were drilled to accept their respective 1/8" diameter x 10mm long 7075 sacrificial drive spurs

( i chose 7075 rather than steel so ,if i were to make a tool contact error, it would be less dramatic a situation for tool and fool )

i turned the spurs on the unimat and trued up the bushings , and cut the counterbores .

both to have excellent runout <.0002" (Yippie!)

to get the correct spur length, i inverted the over lengthened, already sharpened, spur into the socket and faced the ends in the turned bushings.

the spurs were inverted again and were ready for use after some black gun bluing

may i present the spur centers, 35mm OD and 22mm OD

The 35mm drive spur center

The 22mm drive spur center

looking forward to using them!

Thanks for reading!

In preparation i constructed 2, spur drive centers.

they were loosely copied from the OEM style, i did not posses .

i saw the driver in an accessories section of the manual

i started off with 25mm 1215 steel and turned it down to 23.5mm diameter, drilled to 11mm and tapped M12x1.0

i chamfered the stick out, partially parted, and chamfered the other end before parting off the threaded bushing to 15mm long

i repeated the process with a piece of 38mm 1215, it was reduced to 35mm but this time i increased the length to 20mm.

the difference being that i knurled the 35mm section.

after the turning and deburring they were fixed in the vice of the BP

they were drilled to accept their respective 1/8" diameter x 10mm long 7075 sacrificial drive spurs

( i chose 7075 rather than steel so ,if i were to make a tool contact error, it would be less dramatic a situation for tool and fool )

i turned the spurs on the unimat and trued up the bushings , and cut the counterbores .

both to have excellent runout <.0002" (Yippie!)

to get the correct spur length, i inverted the over lengthened, already sharpened, spur into the socket and faced the ends in the turned bushings.

the spurs were inverted again and were ready for use after some black gun bluing

may i present the spur centers, 35mm OD and 22mm OD

The 35mm drive spur center

The 22mm drive spur center

looking forward to using them!

Thanks for reading!