- Joined

- Oct 17, 2023

- Messages

- 36

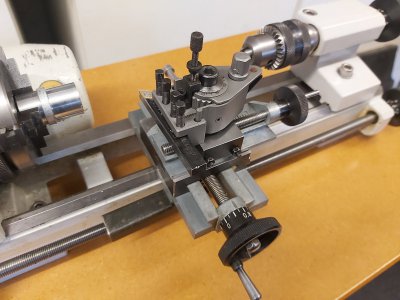

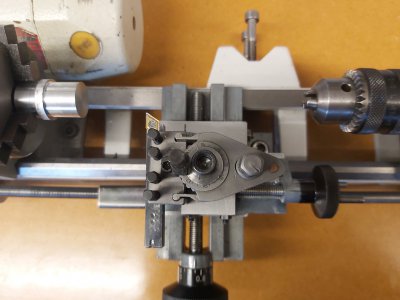

I have just finished doing a few modifications to my Unimat 3 to fit a Multifix style Aaa toolpost.

This is the 3rd Multifix type post that I have purchased from PwWeTools in Germany, the others are fitted to my Compact 5 (Aaa size) and Compact 8 (Aa size). I relly like the functionality and rigidity of these toolposts, they suit my workflow well.

If I had wanted to dispense with using the top slide/compound slide then it would be a simple matter of making up a spacer to sit between the cross slide and underside of the tool post to get centre height on the tool.

I really wanted to retain the compound/top slide but this was placing the 6mm tools at 3mm above centre height, so I had to win back 3mm to get the tool onto centre height.

I could see that it was possible to machine off some material from the top of the cross slide, I chose to machine off 2.25mm here but that took away the recess for the compound centring boss, so that had to be re-instated. I also re-engraved the 0 and 30 degree guide marks on the cross slide which reference the angle that compound slide has been set to.

I got another 0.75mm off of the bottom of the tool holder where it clashed with the top slide.

There was also a significant chunk of metal that needed removing from the old tool post and I got another 0.25mm there, so slightly over the required 3mm.

The tool post works really well and nicely compliments the quality feel of the Unimat 3.

If any one needs more details then just shout out and I will provide them.

This is the 3rd Multifix type post that I have purchased from PwWeTools in Germany, the others are fitted to my Compact 5 (Aaa size) and Compact 8 (Aa size). I relly like the functionality and rigidity of these toolposts, they suit my workflow well.

If I had wanted to dispense with using the top slide/compound slide then it would be a simple matter of making up a spacer to sit between the cross slide and underside of the tool post to get centre height on the tool.

I really wanted to retain the compound/top slide but this was placing the 6mm tools at 3mm above centre height, so I had to win back 3mm to get the tool onto centre height.

I could see that it was possible to machine off some material from the top of the cross slide, I chose to machine off 2.25mm here but that took away the recess for the compound centring boss, so that had to be re-instated. I also re-engraved the 0 and 30 degree guide marks on the cross slide which reference the angle that compound slide has been set to.

I got another 0.75mm off of the bottom of the tool holder where it clashed with the top slide.

There was also a significant chunk of metal that needed removing from the old tool post and I got another 0.25mm there, so slightly over the required 3mm.

The tool post works really well and nicely compliments the quality feel of the Unimat 3.

If any one needs more details then just shout out and I will provide them.

Attachments

Last edited: