- Joined

- Oct 28, 2020

- Messages

- 542

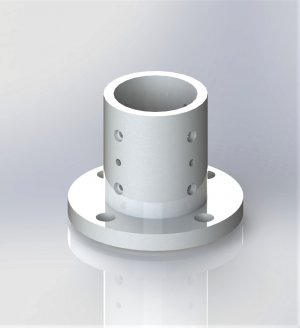

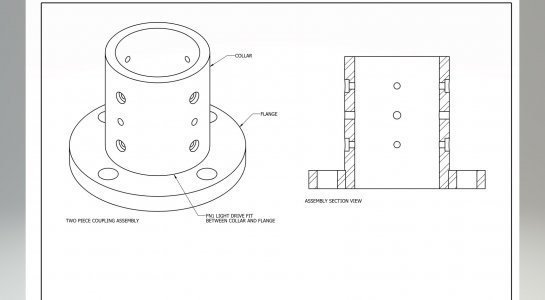

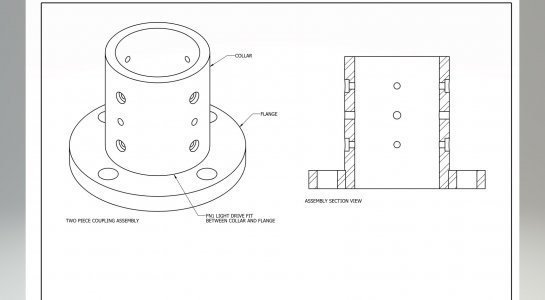

I have an interesting project in my shop just now. This is a two piece flange coupling weldment.

This weldment allows a connection between ceramic lined rubber hose and a 2" pipe. The two pieces consist of a turned collar and a modified pipe flange. The two parts are press fit together and later welded.

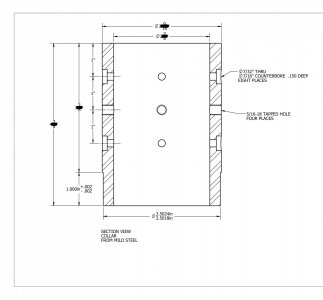

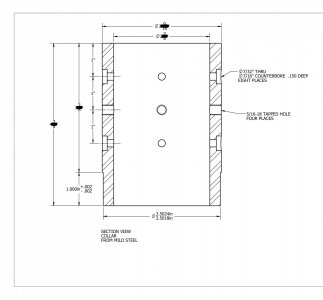

For the collar I ordered some 4140 tubing from McMaster Carr. I was able to find a good size, that allowed for minimal turning and boring.

To create the counter-bored and threaded holes I decided to make up a quick jig from 3" x 3" angle iron.

Using a counter-bore bit was a first for me... but it turned out to be a breeze even when starting on the curved surface of the collar.

Next up will be modifying the flange. I just have to wait a couple of days for it to come in.

Thanks for looking.

This weldment allows a connection between ceramic lined rubber hose and a 2" pipe. The two pieces consist of a turned collar and a modified pipe flange. The two parts are press fit together and later welded.

For the collar I ordered some 4140 tubing from McMaster Carr. I was able to find a good size, that allowed for minimal turning and boring.

To create the counter-bored and threaded holes I decided to make up a quick jig from 3" x 3" angle iron.

Using a counter-bore bit was a first for me... but it turned out to be a breeze even when starting on the curved surface of the collar.

Next up will be modifying the flange. I just have to wait a couple of days for it to come in.

Thanks for looking.