I’m making fishing rod ferrules mainly from bronze. I.e small parts where dimension accuracy and finish is important. I see Sherline makes rear mounted tool holders. Is there any inherent advantage in turning from the rear? I’m pretty satisfied in what I can do now; just chasing that last .0005.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turning from the rear on Sherline lathe.

- Thread starter fcs

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

Just an opinion but I think the Sherline is rigid enough to turn quite well from the front and I see no advantage in going for the increased rigidity you would gain from the rear. The accuracy you're looking for, that last 0.0005", is probably in the geometry of your tool. If you show us your tool we might be able to give you a hand with it.

- Joined

- Feb 15, 2020

- Messages

- 399

Just an opinion but I think the Sherline is rigid enough to turn quite well from the front and I see no advantage in going for the increased rigidity you would gain from the rear. The accuracy you're looking for, that last 0.0005", is probably in the geometry of your tool. If you show us your tool we might be able to give you a hand with it.

I don't understand how rigidity is increased from the back side of a Sherline lathe.

With the tool at the front, cutting forces push down at the tool's tip. The tool post, crosslide, saddle, and lathe bed (all metal parts) are all in compression. There's no cutting force on the flexible plastic gibs.

With the tool at the back, cutting forces pull up at the tool's tip. The saddle is pulled up away from the lathe bed and flexible plastic saddle gib is now in compression. The crosslide is pulled up away from the saddle and the flexible plastic crosslide gib is now in compression.

Am I missing something here?

- Joined

- Dec 20, 2012

- Messages

- 9,422

Yeah, it's hard to visualize. It took me a long time to see it when I first chose to mount a parting tool back there. You're right that the cutting forces at the tip of the tool are directed upwards but it is the tool post that changes things. As I see it, the locking bolt that holds the tool post down acts as a fulcrum and changes the direction of the forces so that they are downward at the rear of the cross slide. Any clearances under the cross slide are taken up and the cutting forces are then transferred to the structure of the lathe. My very rudimentary readings with a tenths indicator suggest that all of this is happening.

There is no question that rigidity is enhanced by rear mounting a cutting tool, whether it is a parting tool, knurling tool or turning tool. How it happens is not settled (except for me) but that isn't what matters. What matters is that it works. If you have not rear mounted your parting tool back there then you really should.

Insofar as the query from the OP, the lathe turns well from the front. How well depends on the tool geometry.

There is no question that rigidity is enhanced by rear mounting a cutting tool, whether it is a parting tool, knurling tool or turning tool. How it happens is not settled (except for me) but that isn't what matters. What matters is that it works. If you have not rear mounted your parting tool back there then you really should.

Insofar as the query from the OP, the lathe turns well from the front. How well depends on the tool geometry.

I can see how cutting from the rear increases the rigidity of the tool. That is what I was missing. A rear mounted tool will not improve my results - I am making small cuts (.010 max) with a sharp tool.

I will get a picture of my tool posted for Mikey’s critique. (Is Mikey really only one person? He seems to answer questions around the clock in a matter of minutes. I suspect he is really some artificial intelligence experiment by Google or Walgreens or somebody. Maybe Elon Musk or Baskin-Robbins.)

I will get a picture of my tool posted for Mikey’s critique. (Is Mikey really only one person? He seems to answer questions around the clock in a matter of minutes. I suspect he is really some artificial intelligence experiment by Google or Walgreens or somebody. Maybe Elon Musk or Baskin-Robbins.)

- Joined

- Dec 20, 2012

- Messages

- 9,422

I forgot to mention that the Sherline lathe is sensitive to gib adjustments. Get it right and it can take cuts that defy belief if you have a good tool.

Show us your tool. If it isn't right, we'll work on it together until it is right.

Show us your tool. If it isn't right, we'll work on it together until it is right.

Here is the ferrule set I made this morning. This is quite a small set. The surface finish appears rough, but will polish out in a few minutes. The ends that go on the rod will be slit. The male slide is turned oversize .001 or probably .002. and fit with #6 cut files or 3M polishing paper while spinning on a mandrel in the lathe.

The material is 630 (nickel-aluminum) bronze which is semi tough to machine (I have read). I know it gets pretty hot in drilling and wants to get really hot reaming. I should have invested in carbide reamers.

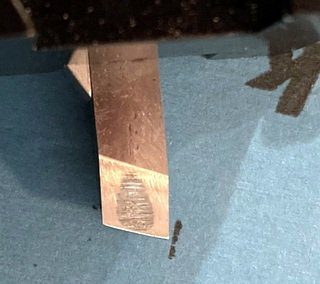

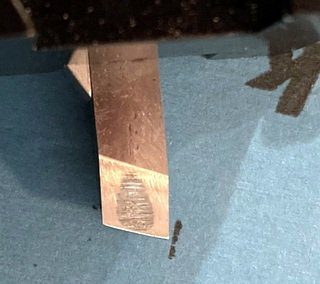

Here is my tool. Not the best photos (not the best phone). It is a simple point with 0 top rake and a small radius at the tip. I have to turn to small shoulders from the left and the right so I just rotate the tool holder to get the side I want approximately square to the work. The shoulders are more decorative than anything; nothing has to seat against them functionally.

As I said, there is nothing really wrong with the final results I'm getting, but if there is something to try I will. Thanks for looking.

The material is 630 (nickel-aluminum) bronze which is semi tough to machine (I have read). I know it gets pretty hot in drilling and wants to get really hot reaming. I should have invested in carbide reamers.

Here is my tool. Not the best photos (not the best phone). It is a simple point with 0 top rake and a small radius at the tip. I have to turn to small shoulders from the left and the right so I just rotate the tool holder to get the side I want approximately square to the work. The shoulders are more decorative than anything; nothing has to seat against them functionally.

As I said, there is nothing really wrong with the final results I'm getting, but if there is something to try I will. Thanks for looking.

- Joined

- Feb 15, 2020

- Messages

- 399

Yeah, it's hard to visualize. It took me a long time to see it when I first chose to mount a parting tool back there. You're right that the cutting forces at the tip of the tool are directed upwards but it is the tool post that changes things. As I see it, the locking bolt that holds the tool post down acts as a fulcrum and changes the direction of the forces so that they are downward at the rear of the cross slide. Any clearances under the cross slide are taken up and the cutting forces are then transferred to the structure of the lathe. My very rudimentary readings with a tenths indicator suggest that all of this is happening.

There is no question that rigidity is enhanced by rear mounting a cutting tool, whether it is a parting tool, knurling tool or turning tool. How it happens is not settled (except for me) but that isn't what matters. What matters is that it works. If you have not rear mounted your parting tool back there then you really should.

Insofar as the query from the OP, the lathe turns well from the front. How well depends on the tool geometry.

I guess it doesn't much matter on a tool this small. Sherline's compound slide works from the back just fine.

Last edited:

- Joined

- Dec 20, 2012

- Messages

- 9,422

Your tool is called a Round Nose Tool. As shaped, it will cut in both directions, which is sort of nice when you have to turn out a section between shoulders; that is what the tool was designed for. The problem with this tool is that it won't cut a sharp shoulder and the finish may be limited by what can be achieved with just the nose radius. Harder materials like aluminum bronze can leave a "spirally" finish.

If I were going to make ferrules, I would approach it a bit differently. I would definitely use my rear mounted parting tool to demarcate the shoulders so I have a nice clean shoulder to turn up to. Then I would grind a RH turning tool so I can change the lead angle and use my edges to finish. I would grind such a tool with 12-15 degrees of side and end relief and I would grind 5-8 degrees of side rake and zero back rake. I would keep the nose radius small, in the 1/64" to 1/32" range, no bigger. If in doubt about how to grind these angles, see this article.

In use, I would initially position the tool with the shank perpendicular to the work to see how that goes. If it chatters, turn the tip of the tool towards the chuck a bit and play with it until it cuts clean. This is called reducing your lead angle and as you do this, the cutting forces at the tip drop. If the finish is not sufficient, try cutting with the area just behind the nose radius on the end cutting edge. It's almost like taking a facing cut except you're cutting along the axis of the work with the end edge instead of the side edge. Very light cuts like this are actually shearing cuts and typically enable a very fine and accurate finish. This is actually why I suggest adding the side rake; to give you this shearing capability at the end edge.

Oh, the other thing that works well with this class of material is to increase your speed with finishing cuts and slow the feed. This, too, reduces cutting forces (increasing the speed) and makes for a very nice finish.

Give this a try and let us know how it goes.

If I were going to make ferrules, I would approach it a bit differently. I would definitely use my rear mounted parting tool to demarcate the shoulders so I have a nice clean shoulder to turn up to. Then I would grind a RH turning tool so I can change the lead angle and use my edges to finish. I would grind such a tool with 12-15 degrees of side and end relief and I would grind 5-8 degrees of side rake and zero back rake. I would keep the nose radius small, in the 1/64" to 1/32" range, no bigger. If in doubt about how to grind these angles, see this article.

In use, I would initially position the tool with the shank perpendicular to the work to see how that goes. If it chatters, turn the tip of the tool towards the chuck a bit and play with it until it cuts clean. This is called reducing your lead angle and as you do this, the cutting forces at the tip drop. If the finish is not sufficient, try cutting with the area just behind the nose radius on the end cutting edge. It's almost like taking a facing cut except you're cutting along the axis of the work with the end edge instead of the side edge. Very light cuts like this are actually shearing cuts and typically enable a very fine and accurate finish. This is actually why I suggest adding the side rake; to give you this shearing capability at the end edge.

Oh, the other thing that works well with this class of material is to increase your speed with finishing cuts and slow the feed. This, too, reduces cutting forces (increasing the speed) and makes for a very nice finish.

Give this a try and let us know how it goes.