I already have Halligan142's formula for tailstock offset written down in my notebook. I have learned a lot from his videos.

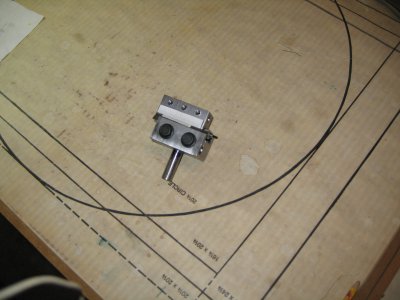

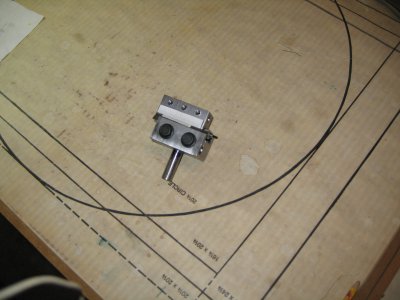

Back to the project at hand. This bull nose live center is heavy. It weighs 12 lbs. No way am I going to use an adapter hanging off of the tailstock ram. Here is a picture of the shaft.

The straight end already has a center hole. The tapered end needs a center hole if I am going to use the off set taper method. I actually don't need to off set the tailstock because I made a boring bar holder primarily to have the ability to turn tapers without off setting the tailstock.

I found a morse taper chart online. The taper per inch for a MT2 is .500. The taper per inch for a MT3 is .502. If I use the compound method is the MT3 taper close enough to MT2 taper that I can use the existing taper on the shaft to set the angle of the compound?

This is my order of operation (wrong term?) if I use the compound method.

1. Dial in the shaft in a 4 jaw.

2. Drill a center hole in the taper end.

3. Turn the headstock end of the existing taper to .700. Say 1/2" to 1" long. .700 is the max OD of a MT2 taper.

4. Measure 2.5" from where I want the taper to end and turn the rest of the shaft to .5720. The minimum OD of a MT2 taper. I want to have a tang on the end to be able to push the live center out of the tailstock ram.

5. Set the compound to the same taper as the existing taper.

6. Turn the taper cutting towards the tailstock. Or cutting towards the headstock. Does the direction of cut matter? I always prefer cutting towards the headstock because I have had problems in the past with the work pulling out of the chuck when cutting towards the tailstock.

7. Part off the end leaving a short tang. Say 3/8" to 1/2."

I will have to check the length of travel on the compound. I recall it being just over 2 inches.

For the off set method this is my order operation.

1. Dial in the shaft in a 4 jaw.

2. Drill a center hole in the taper end.

3. Turn the taper end of the shaft to .700.

4. Measure 2.5" from where I want the taper to end and turn the rest of the shaft to .5720. The minimum OD of a MT2 taper. I want to have a tang on the end to be able to push the live center out of the tailstock ram.

5. Calculate the amount of off set.

6. Set the shaft between centers with the tailstock end off set as calculated.

7. Turn the taper cutting towards the headstock.

8. Part off the end leaving a short tang. Say 3/8" to 1/2."

What have I left out?