- Joined

- Oct 30, 2019

- Messages

- 225

A while back we bought a commercial kitchen pre-wash station from an auction, so that we could set up in our basement to blast dirt and bugs off of produce from the garden and do some other light processing work before canning/freezing, etc. This would prevent us from taking over the kitchen for those times, plus give somewhere for produce to drip dry and the potentially high volumes of plain rinse water can go out our sump pump instead of into our septic system

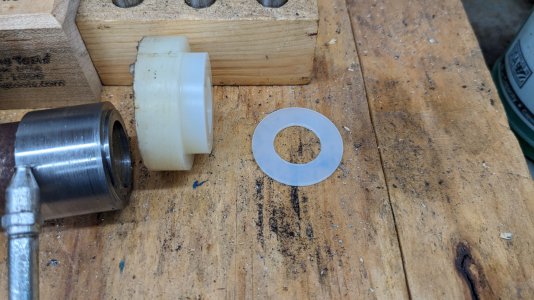

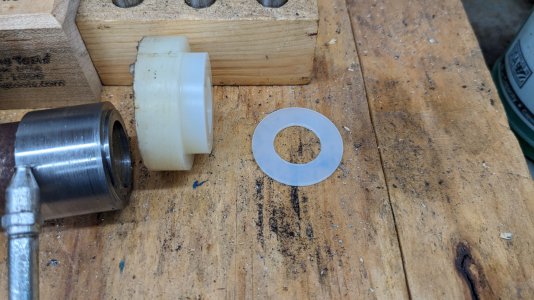

Took the sprayer off the sink for transport. In doing so lost one of the washers used to connect the sprayer valve manifold to the inlets, and the other one was hard/old/chewed up.

Deviced to make new ones from an offcut of what is probably HDPE

Pretty straight forward, turned the OD down to just smaller than the minor diameter of the female threads (approximately 1-3/16), and drilled the ID to roughly the size of the hex broached into the mating surface (13/16)

Then parted off with the insert parting tool and fine feed, which worked better than I expected - I was most worried about if the parting operation would gall the surface, since that is the most critical feature to seal properly

Installed and sealed up great

Took the sprayer off the sink for transport. In doing so lost one of the washers used to connect the sprayer valve manifold to the inlets, and the other one was hard/old/chewed up.

Deviced to make new ones from an offcut of what is probably HDPE

Pretty straight forward, turned the OD down to just smaller than the minor diameter of the female threads (approximately 1-3/16), and drilled the ID to roughly the size of the hex broached into the mating surface (13/16)

Then parted off with the insert parting tool and fine feed, which worked better than I expected - I was most worried about if the parting operation would gall the surface, since that is the most critical feature to seal properly

Installed and sealed up great