- Joined

- Jan 3, 2015

- Messages

- 400

Back in April, once I got my G0704 CNC conversion finished, I posted a thread about ideas for ease of use. Several of us got into a discussion about the TTS. I ended up putting that on the back burner as a couple of summer vacation trips were coming and it seemed like there was no rush to get a TTS running. I got my Z-axis touch plate working (also part of that discussion), built a couple of tooling plates (ditto), spent entirely too much time on my GB-22 (single shot .22 pistol that never did work right) and now that the trip to see the eclipse is over, started playing with thoughts of the TTS again.

One of the things I had concluded about the TTS is that it really only improves the speed with which you change tools. I can very easily convince myself that since I'm not trying to make money from my shop, that speed doesn't matter. Why do I say this? Every tool I put in my spindle has the same center. Once I define where (0,0) is , the only thing left to zero is Z, and that's the easiest thing to zero - especially with my touch plate. Even without the touch plate, bumping Z down .001 at a time until I touch a feeler gage or the top of the work, is easy with my hand controller. So the TTS saves me the time of finding zero for all tools, since I can put every tool in a tool table in Mach3 with its length offset. That figures to be a minute per tool change, but let's say it's five minutes. So what?

What else does the TTS buy me?

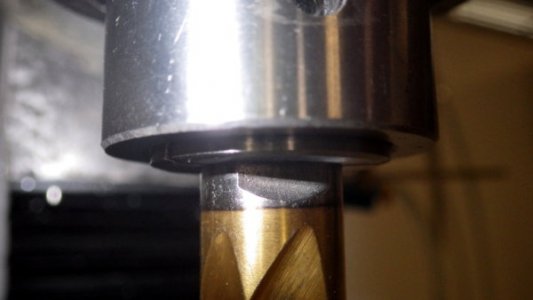

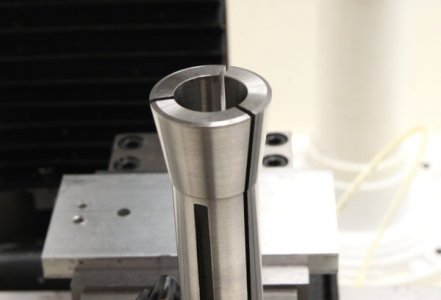

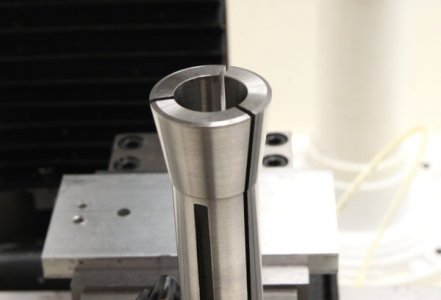

The TTS is based around a special 3/4" R8 collet that is ground flat across its top. Little Machine Shop has a description and picture here. In that original post, Spumco had posted a link to eBay seller cncmachinetool as a source of parts that interchange with some TTS parts. I went there and found some 3/4 R8 collets, so I thought I'd get one and see if I could cut or grind it flat so that it looked like the TTS "master". This is what I got. It's already ground flat:

I haven't put this in my spindle yet and tried to make any measurements of TIR, or even make sure it fits, but I really don't doubt that. It seems just like the 3/4" collet that I got in a set when I bought the Grizz, except for being ground flat and not slightly domed toward the center. I did try one of my 3/4 tools in it and the opening seems just right.

It looks like it would work as a TTS collet to me, but I don't have one to compare to. Does anyone with experience have any input on this?

This is probably too rambling, but I'm a hobby guy and it just seems like it adds a lot of expense and complication, all of which serves only to get projects done a little faster. Am I missing something?

One of the things I had concluded about the TTS is that it really only improves the speed with which you change tools. I can very easily convince myself that since I'm not trying to make money from my shop, that speed doesn't matter. Why do I say this? Every tool I put in my spindle has the same center. Once I define where (0,0) is , the only thing left to zero is Z, and that's the easiest thing to zero - especially with my touch plate. Even without the touch plate, bumping Z down .001 at a time until I touch a feeler gage or the top of the work, is easy with my hand controller. So the TTS saves me the time of finding zero for all tools, since I can put every tool in a tool table in Mach3 with its length offset. That figures to be a minute per tool change, but let's say it's five minutes. So what?

What else does the TTS buy me?

The TTS is based around a special 3/4" R8 collet that is ground flat across its top. Little Machine Shop has a description and picture here. In that original post, Spumco had posted a link to eBay seller cncmachinetool as a source of parts that interchange with some TTS parts. I went there and found some 3/4 R8 collets, so I thought I'd get one and see if I could cut or grind it flat so that it looked like the TTS "master". This is what I got. It's already ground flat:

I haven't put this in my spindle yet and tried to make any measurements of TIR, or even make sure it fits, but I really don't doubt that. It seems just like the 3/4" collet that I got in a set when I bought the Grizz, except for being ground flat and not slightly domed toward the center. I did try one of my 3/4 tools in it and the opening seems just right.

It looks like it would work as a TTS collet to me, but I don't have one to compare to. Does anyone with experience have any input on this?

This is probably too rambling, but I'm a hobby guy and it just seems like it adds a lot of expense and complication, all of which serves only to get projects done a little faster. Am I missing something?