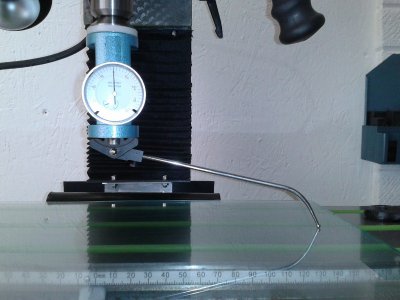

I'm an old, retired, wanna-be machinist with a little experience on a Unimat years ago. In November I picked up an LMS lathe and in January an LMS mill. After getting things mounted and organized I wanted to "tram" (square) the mill. I found some references to using a machined disc as a surface for measurement. So I thought since I don't have a disc, perhaps a glass surface would do the job. I bought a sheet of 1/4" plate glass and after wiping down the table and the glass thoroughly it worked just fine. Anyone else tried this? Is there any reason to not use glass?

I also built a heavy duty rolling (with caster locks) stand with drawers for the mill. Seems quite stable and easy to move out of the way when not in use.

I also built a heavy duty rolling (with caster locks) stand with drawers for the mill. Seems quite stable and easy to move out of the way when not in use.