- Joined

- Oct 31, 2016

- Messages

- 2,720

When I bought my home a few years back the prior owner had left behind a very sturdy home built utility trailer. This afternoon I decided to check out the bearings, etc to see if it was worth getting the trailer registered and start using it. Jacked up the right side and the hub was very loose. I thought to myself looks like I got a bad bearing. Took it apart and the bearings were fine. The grease seal looked like it needed replacement but I didn't notice anything else that looked a miss except it looked like the grease seal had been rubbing on the spindle backing plate.

Jacked up the left side and everything seemed ok. Took the hub off. No problems with the bearings and the grease seal looked like it needed replacement also but had not been rubbing on the backing plate. Swapped the hubs side to side. The right side hub on the left spindle fit just fine and was not loose. But the left side hub now on the right spindle was loose and sloppy. What's up with that???

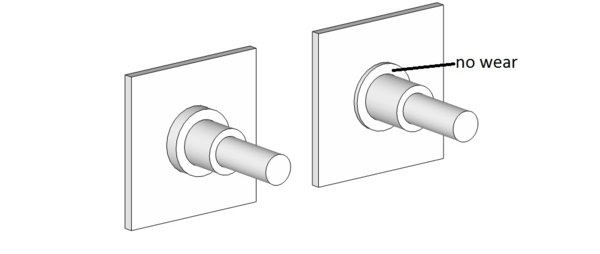

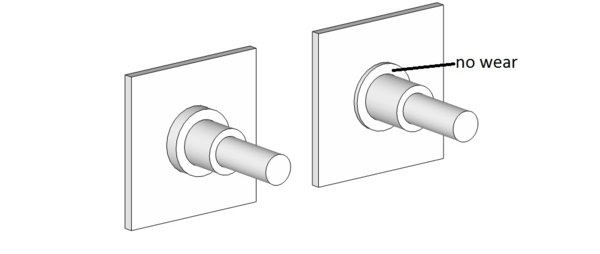

I looked at the spindles and discovered that they were slightly different in one place. The spindles have three bearing surfaces. One for the grease seal, one for the inner bearing and one for the outer bearing. The difference in the spindles is the length of the grease seal and inner bearing surfaces. The left side grease seal bearing surface is approximately 3/8" long whereas the right side grease seal bearing surface is approximately 1/8" long. And the inner bearing surfaces are different in length by the same amount with the right side being approximately 1/4" longer than the left side. The inner bearing fits up against the face of the grease seal. This is what keeps the hub in proper position on the spindle. There is no evidence of wear on the right side face. Looks like it was made that way.

I think that I can solve the problem by machining a spacer to increase the length of the grease seal surface and decrease the length of the inner bearing surface. I would think that this spacer would need to be a press fit. Or would it be ok if it should happen to rotate. The force of the inner bearing should hold it in place. I would of course slather this spacer with wheel bearing grease. Also how precise would the thickness of this spacer need to be.

Any and all suggestions would be appreciated.

Jacked up the left side and everything seemed ok. Took the hub off. No problems with the bearings and the grease seal looked like it needed replacement also but had not been rubbing on the backing plate. Swapped the hubs side to side. The right side hub on the left spindle fit just fine and was not loose. But the left side hub now on the right spindle was loose and sloppy. What's up with that???

I looked at the spindles and discovered that they were slightly different in one place. The spindles have three bearing surfaces. One for the grease seal, one for the inner bearing and one for the outer bearing. The difference in the spindles is the length of the grease seal and inner bearing surfaces. The left side grease seal bearing surface is approximately 3/8" long whereas the right side grease seal bearing surface is approximately 1/8" long. And the inner bearing surfaces are different in length by the same amount with the right side being approximately 1/4" longer than the left side. The inner bearing fits up against the face of the grease seal. This is what keeps the hub in proper position on the spindle. There is no evidence of wear on the right side face. Looks like it was made that way.

I think that I can solve the problem by machining a spacer to increase the length of the grease seal surface and decrease the length of the inner bearing surface. I would think that this spacer would need to be a press fit. Or would it be ok if it should happen to rotate. The force of the inner bearing should hold it in place. I would of course slather this spacer with wheel bearing grease. Also how precise would the thickness of this spacer need to be.

Any and all suggestions would be appreciated.