- Joined

- Apr 4, 2013

- Messages

- 884

Greetings,

Family is coming in an hour for the Christmas Eve dinner, but I figured I can slip in a quick project status update.

This week I wrapped up a big chunk of work related to the Saved Tool Offset Memory and dealing with tools offset in general. I ended up completely re-doing a lot of that functionality since I wasn't too happy with how it works in the current version (V2.5). Here are some of the things that are coming:

A simpler way to add a new tool to the Saved Tool Offset Memory.

The process on a mill is as follows:

A more obvious way to set and visualize the direction of the tool radius compensation.

The dialog that is used to set the compensation now has graphical buttons that make it clear what the relationship between the cutter and the workpiece will be. Cutter diameter and offset is now shown in the graphical view as well and can be quickly changed from there.

Finally, the feature that I find myself using a lot is the new "Hold Position" function. It's very simple - pressing the button freezes the readout and then sets the position to that value when you press the button again. It makes swapping cutters so much faster though:

Touch-of the old cutter

These are just some of the highlights. A more detailed list is posted on Yuriy's Toys site. I would love to hear your feedback, either here or in the comments on the blog. If things go well, I hope to have this in "private Alpha" in February. If you are interested tobecome a willing crash test dummy try some of these features in Alpha, please let me know.

Best regards

Yuriy

Family is coming in an hour for the Christmas Eve dinner, but I figured I can slip in a quick project status update.

This week I wrapped up a big chunk of work related to the Saved Tool Offset Memory and dealing with tools offset in general. I ended up completely re-doing a lot of that functionality since I wasn't too happy with how it works in the current version (V2.5). Here are some of the things that are coming:

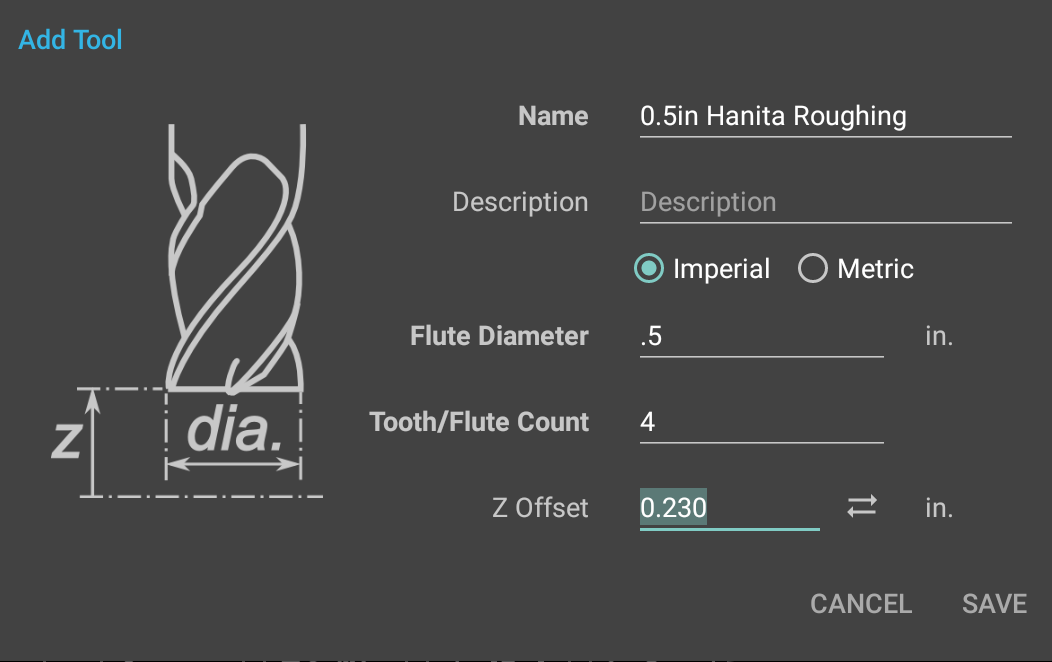

A simpler way to add a new tool to the Saved Tool Offset Memory.

The process on a mill is as follows:

- Insert an existing tool (doesn't need to be the "reference" tool; any tool in the library works)

- Click "Set Z Offset", select the tool from the list and apply its Z offset

- Using a feeler gauge, touch the tool off to the surface of your table/vise/etc.

- Zero out the Z-axis

- Insert the new tool

- Use the same feeler gauge to touch off the new too

- Open the "Add New Tool" dialog, enter the name, diameter, flute count and press the "Sync" button next to the Z Offset

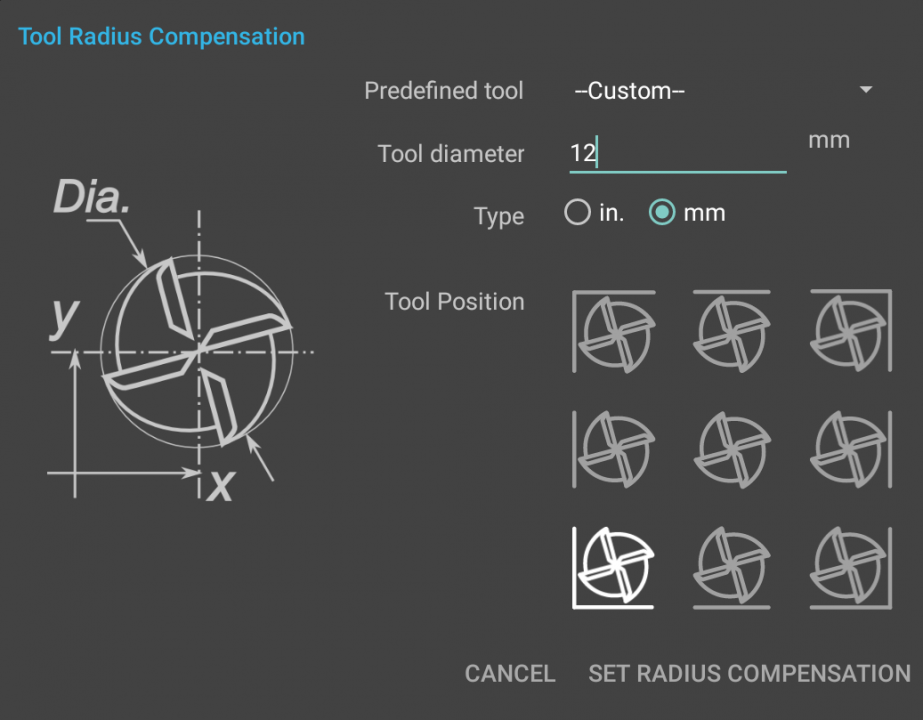

A more obvious way to set and visualize the direction of the tool radius compensation.

The dialog that is used to set the compensation now has graphical buttons that make it clear what the relationship between the cutter and the workpiece will be. Cutter diameter and offset is now shown in the graphical view as well and can be quickly changed from there.

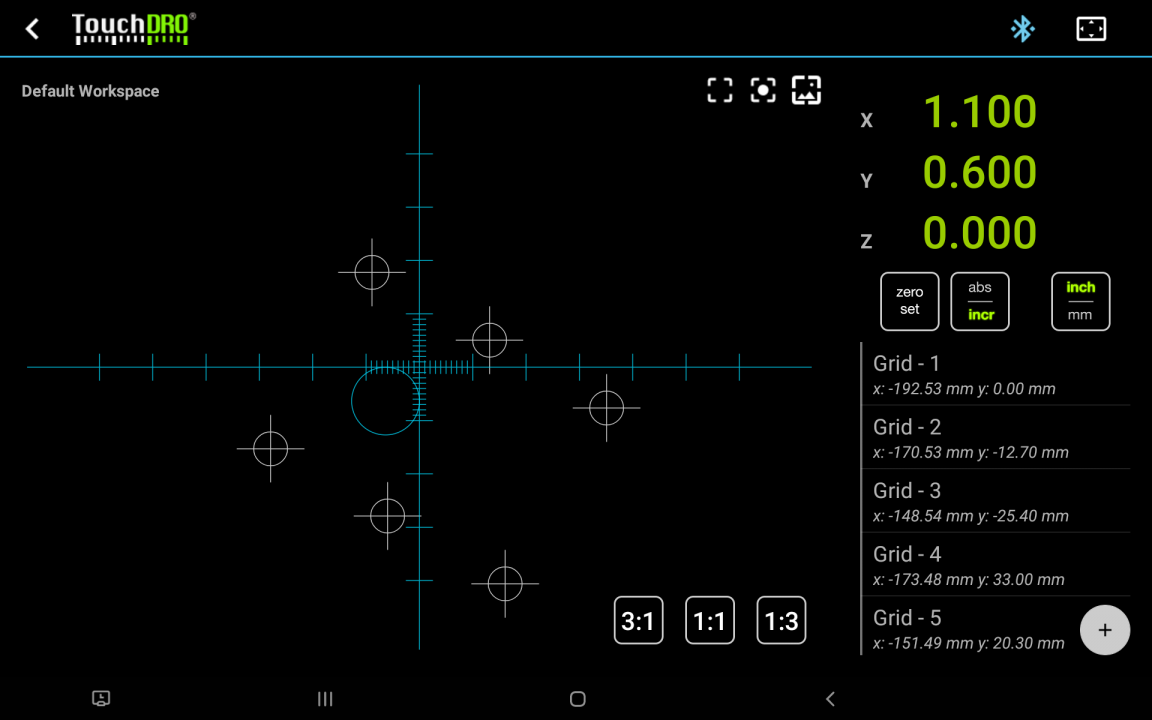

Finally, the feature that I find myself using a lot is the new "Hold Position" function. It's very simple - pressing the button freezes the readout and then sets the position to that value when you press the button again. It makes swapping cutters so much faster though:

Touch-of the old cutter

- Press "Hold"

- Insert the new cutter

- Touch it off

- Press "Hold" again

These are just some of the highlights. A more detailed list is posted on Yuriy's Toys site. I would love to hear your feedback, either here or in the comments on the blog. If things go well, I hope to have this in "private Alpha" in February. If you are interested to

Best regards

Yuriy