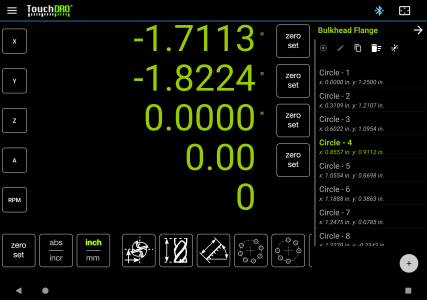

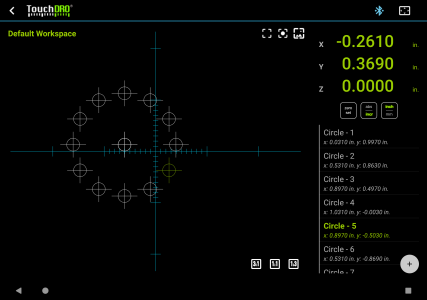

Each axis will have its own Zero. You will also have the absolute and incremental systems that you can use. Zeroing one does not zero the other so you can switch back and forth and not loose your zero in the other. Didn't a manual come with it? You will need one to learn all the functions on a DRO. The dials on some lathes are calibrated for diameter, some for radius. Probably best to set the DRO to match. I use diameter settings since that's the way most things are given. A "D" is displayed when in the diameter mode. Hardest thing about mounting the scales is to insure the read head is traveling correctly relative to the scale. There is also a calibration routine so you can match the dials to the DRO or to some other standard. One thing that got much easier for me was getting the taper attachment set dead on by using the DRO. By measuring the work with a micrometer and then entering that value in the DRO, you can tell exactly how far you need to go yet after multiple passes. Before the last pass I check again with the micrometer just to be sure. Being able to switch between Imperial and metric is handy, so is the calculator function. I'm not familiar with the Touch brand, mine are Easson. You will like your new DRO!