- Joined

- May 27, 2016

- Messages

- 3,479

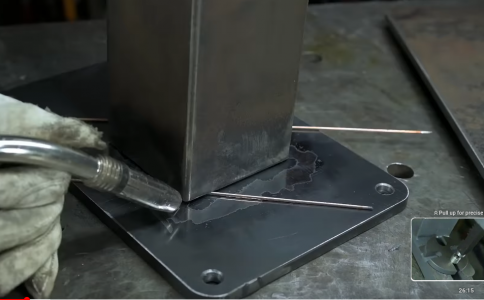

This Old Tony posted a new video on YT about things he did for his arbor press. At one stage, he sets up a deliberate gap, using welding rod.

What is is primary motivation for adopting this technique. What are the advantages?

-

-

After the usual tack welds, he then completes all the way around.

The actual video is here ->

What is is primary motivation for adopting this technique. What are the advantages?

-

-

After the usual tack welds, he then completes all the way around.

The actual video is here ->