- Joined

- Jan 17, 2017

- Messages

- 16

Gentlemen -

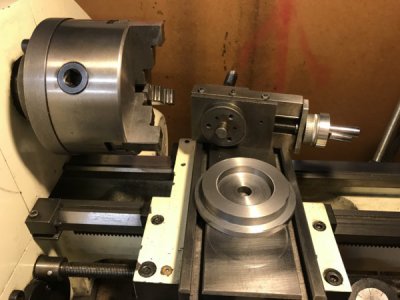

I have an OXO-size QCTP from LMS mounted on my Jet 9x20.

Since the tool holders are big enough to accept 1/2" stock, I bought a SHARS 1/2" indexable insert set, rationalizing that even if the lathe can't take advantage of the additional rigidity over 3/8" stock, it can't hurt. I know, silly newbie mistake.

Problem: Unmodified, the stack-up is too tall for the 1/2" tools by something less than 0.125" (haven't measured). I don't have ready access to a mill to shave the top of the compound or to shave the bottoms of the holders. I can probably encourage a better-equipped friend to do a little mill-based adjustment if needed. I have filed a relief on the corner of the compound that allows the tool holders to drop low enough to get the correct cutting height for the few tools that I have.

Two questions come to mind:

1. Given the natural "strength" of the 9x20-size machines, is there any advantage to be gained with 1/2" vs. 3/8" tool holders?

2. The first order of business is a Pitkin Donut. Would you consider it wise to either make the donut thinner or shave the top of the compound to allow the QCTP to accept 1/2" tooling?

Neal

I have an OXO-size QCTP from LMS mounted on my Jet 9x20.

Since the tool holders are big enough to accept 1/2" stock, I bought a SHARS 1/2" indexable insert set, rationalizing that even if the lathe can't take advantage of the additional rigidity over 3/8" stock, it can't hurt. I know, silly newbie mistake.

Problem: Unmodified, the stack-up is too tall for the 1/2" tools by something less than 0.125" (haven't measured). I don't have ready access to a mill to shave the top of the compound or to shave the bottoms of the holders. I can probably encourage a better-equipped friend to do a little mill-based adjustment if needed. I have filed a relief on the corner of the compound that allows the tool holders to drop low enough to get the correct cutting height for the few tools that I have.

Two questions come to mind:

1. Given the natural "strength" of the 9x20-size machines, is there any advantage to be gained with 1/2" vs. 3/8" tool holders?

2. The first order of business is a Pitkin Donut. Would you consider it wise to either make the donut thinner or shave the top of the compound to allow the QCTP to accept 1/2" tooling?

Neal