- Joined

- Feb 24, 2017

- Messages

- 11

Hello all,

I have what I hope is a simple question for the more experienced machinist on this forum, but one that is not readily explained in the internet searches I have performed.

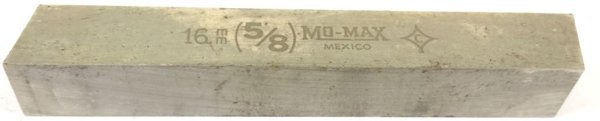

I inherited a lot of Tool Steel from my father when he passed away and some additional pieces with a machine I recently purchased. There is quite a lot of it - maybe 50 lbs or so and some larger pieces so I would like to understand what I have and make use of it. For the most part it isn't marked other than hand written tool steel presumably by my father. A few of the pieces I got with my machine are factory marked "Jacobs Purple Label Extra" and "Mo-Max High Speed". I would have expected this Tool Steel to be provided in an annealed state (like drill rod) for machining but they all seem to be quite hard. It is very difficult if not impossible to cut with a hack saw blade.

Can someone please enlighten me?

I have what I hope is a simple question for the more experienced machinist on this forum, but one that is not readily explained in the internet searches I have performed.

I inherited a lot of Tool Steel from my father when he passed away and some additional pieces with a machine I recently purchased. There is quite a lot of it - maybe 50 lbs or so and some larger pieces so I would like to understand what I have and make use of it. For the most part it isn't marked other than hand written tool steel presumably by my father. A few of the pieces I got with my machine are factory marked "Jacobs Purple Label Extra" and "Mo-Max High Speed". I would have expected this Tool Steel to be provided in an annealed state (like drill rod) for machining but they all seem to be quite hard. It is very difficult if not impossible to cut with a hack saw blade.

Can someone please enlighten me?