- Joined

- Oct 31, 2016

- Messages

- 2,720

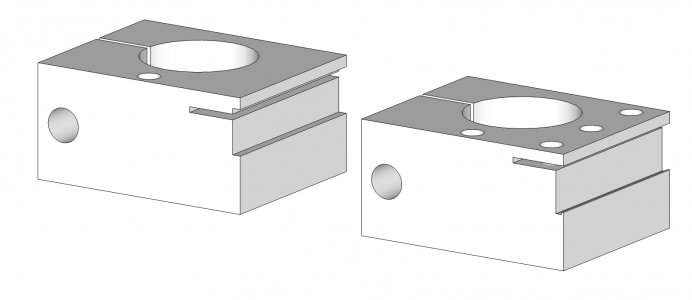

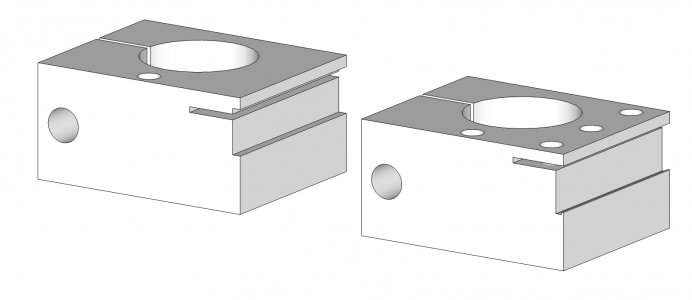

I needed some more tool holders. Don't we always need more tool holders? I especially needed one for my parting blade. So this week I have been working on 3 more tool holders. I like the angled tool holders I have made in the past and am making two more. The third holder is for my parting blade.

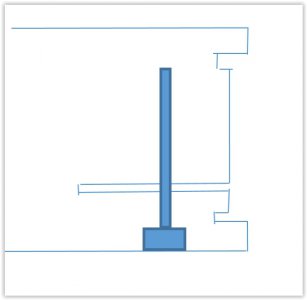

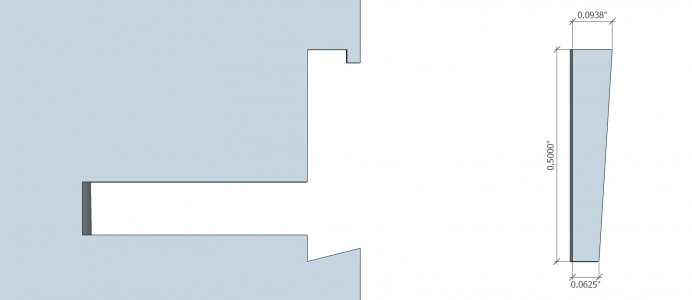

I had my parting blade held in one of my typical tool holders and it worked well. Until last week when I needed to part off a part right up against the chuck. I had to drag out one of my old craftsman parting blade holders and it barely cleared the chuck. Time to make one. There have been some threads recently where the top lip of the tool holder is tightened down on the parting blade to hold the blade in place. Winky"s Workshop has a video on one he made. I like this concept because the blade is right on the edge of the tool holder. All of my parting blades have the typical triangle shape. I know the consensus is the the T shaped blades are better but I don't want to buy another parting blade. I think that I already have a lifetime supply of parting blades. What I would like to get suggestions on is the shape of the slot that holds the blade and where the clamping slit should be positioned. Below is a drawing with a couple of possibilities.

Help me out.

I had my parting blade held in one of my typical tool holders and it worked well. Until last week when I needed to part off a part right up against the chuck. I had to drag out one of my old craftsman parting blade holders and it barely cleared the chuck. Time to make one. There have been some threads recently where the top lip of the tool holder is tightened down on the parting blade to hold the blade in place. Winky"s Workshop has a video on one he made. I like this concept because the blade is right on the edge of the tool holder. All of my parting blades have the typical triangle shape. I know the consensus is the the T shaped blades are better but I don't want to buy another parting blade. I think that I already have a lifetime supply of parting blades. What I would like to get suggestions on is the shape of the slot that holds the blade and where the clamping slit should be positioned. Below is a drawing with a couple of possibilities.

Help me out.