- Joined

- Jan 2, 2019

- Messages

- 7,162

I bought this really cool small tool grinder a little while back.

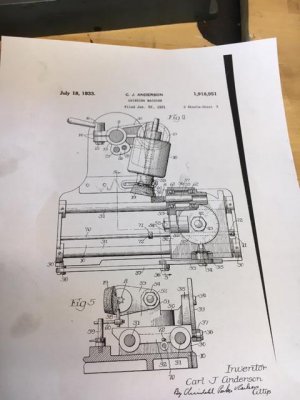

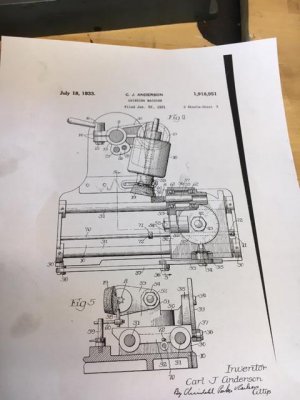

It was set up for grinding reamers but not much else so I started doing some research. All I could find online was the original patent filing from 1933, it showed another piece that I didn't get which looked perfect for grinding drills and end mills.

So I decided to try and duplicate it based on the drawing. There weren't any dimensions so I had to figure those out, fortunately I had a few pieces of steel that looked about right. I started with the base.

Then I needed to have some kind of tool holder. Fortunately I had an ER32 - MT2 collet holder and a Hardinge MT2 - straight shank taper thing I bought off eBay to work with, I made a knurled piece to serve as a drawbar holder (5/16 cap screw).

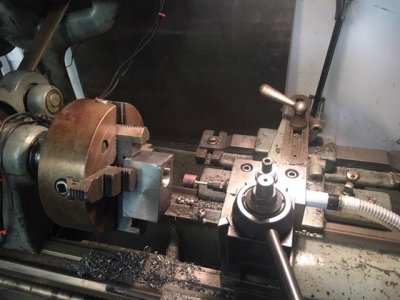

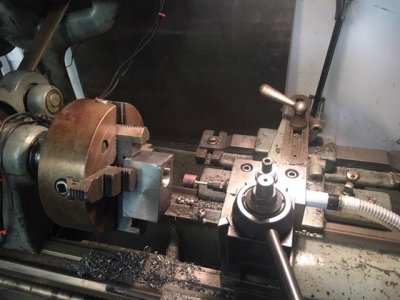

I had a piece of scrap left from my other project that was about the right size but since it was from the end of the bar it was pretty buggered up. I squared it up on the lathe and bored and offset hole for my collet arrangement.

I wanted a nice finish inside with a good slip fit so I did the final sizing with a makeshift tool post grinder (HF mini die grinder).

Roughed out a pedestal for the base and started removing material from the collet holder block.

Much layout, cutting, drilling, tapping, grinding, filing, and sanding and I think I have a pretty passable copy of the original from the patent drawing.

Ready to go to work sharpening tools.

Thanks for looking.

John

It was set up for grinding reamers but not much else so I started doing some research. All I could find online was the original patent filing from 1933, it showed another piece that I didn't get which looked perfect for grinding drills and end mills.

So I decided to try and duplicate it based on the drawing. There weren't any dimensions so I had to figure those out, fortunately I had a few pieces of steel that looked about right. I started with the base.

Then I needed to have some kind of tool holder. Fortunately I had an ER32 - MT2 collet holder and a Hardinge MT2 - straight shank taper thing I bought off eBay to work with, I made a knurled piece to serve as a drawbar holder (5/16 cap screw).

I had a piece of scrap left from my other project that was about the right size but since it was from the end of the bar it was pretty buggered up. I squared it up on the lathe and bored and offset hole for my collet arrangement.

I wanted a nice finish inside with a good slip fit so I did the final sizing with a makeshift tool post grinder (HF mini die grinder).

Roughed out a pedestal for the base and started removing material from the collet holder block.

Much layout, cutting, drilling, tapping, grinding, filing, and sanding and I think I have a pretty passable copy of the original from the patent drawing.

Ready to go to work sharpening tools.

Thanks for looking.

John