- Joined

- Apr 12, 2013

- Messages

- 562

I am building a spider (replacing the preload collar with a long collar that can be threaded for 4 set secrews) to fit the left side of my spindle on my 10F, and in the course of setup I checked the threads on the existing threaded preload/retainer collar. Upon reinstall I snugged the collar down and tightened an additional rotation of about 2 teeth of the drive gear that drives the leadscrew gear train. I was going from memory but I recalled that was the preload recommended in the assembly manual.

My question: Previously the spindle was loose enough that even with the drive belt lever pulled forward (disengaged) belt friction would (slowly) spin up an unloaded spindle. This no longer happens when the belt is set for higher speeds. The idler pulley is spinning under a stationary spindle drive belt. Once the tension lever is started back to lock in the drive belt the spindle quickly spins up and works fine.

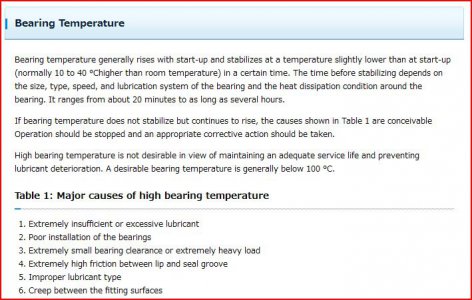

Did I set the bearing preload collar too tight? After running for about an hour at 684 RPM turning down a block of wood the right bearing area (near the oiler, for example) of the headstock casting was slightly warmer than ambient...it was noticeable but far from uncomfortable...maybe 10-15 degree rise. This is new. Previously there was no detectable difference in temperature form the bearing area to any other part of the headstock casting.

I am running Mobil (Vactra?) Spindle Oil...a squirt before startup and a half dozen drops every 5-10 minutes of operation because the oil just flows right through.

My question: Previously the spindle was loose enough that even with the drive belt lever pulled forward (disengaged) belt friction would (slowly) spin up an unloaded spindle. This no longer happens when the belt is set for higher speeds. The idler pulley is spinning under a stationary spindle drive belt. Once the tension lever is started back to lock in the drive belt the spindle quickly spins up and works fine.

Did I set the bearing preload collar too tight? After running for about an hour at 684 RPM turning down a block of wood the right bearing area (near the oiler, for example) of the headstock casting was slightly warmer than ambient...it was noticeable but far from uncomfortable...maybe 10-15 degree rise. This is new. Previously there was no detectable difference in temperature form the bearing area to any other part of the headstock casting.

I am running Mobil (Vactra?) Spindle Oil...a squirt before startup and a half dozen drops every 5-10 minutes of operation because the oil just flows right through.