- Joined

- Sep 5, 2013

- Messages

- 3,746

Every time I cut something on my bandsaw I think of this little trick I use and wonder if anyone else might find it useful. So....

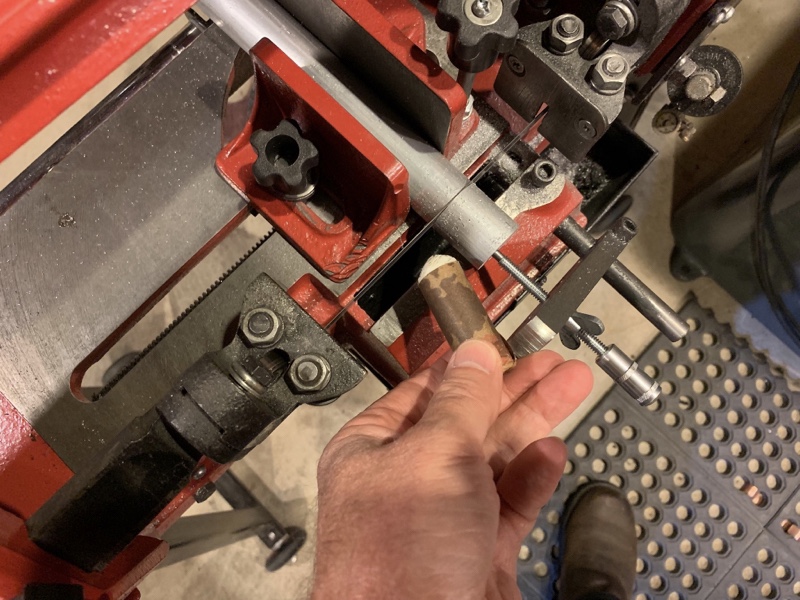

Like a lot of folks, I use a stick wax blade lubricant on the bandsaw. Comes in a cardboard tube about 2” in diameter and six inches long or so. I use Formax, but there are others, doesn’t matter. I like it, but always found the big tube awkward if I’m cutting something small. So I figured I’d downsize a bit.

Canada discontinued use of the copper penny a few years ago so I ended up with a surplus of paper coin rolling tubes. Turns out they are the exact same diameter as an electrical box knockout (everybody saves those, right?). So I poked one knockout down to the bottom of an empty tube, melted some chips of the Formax in an old tin can and poured in a half-inch or so. In a few minutes it was solid enough to pour the rest of the tube full and let it cool.

In use it works just like a crayon and I can get in close while the cut is in progress. And with the addition of a tiny magnet on the bottom of the knockout, it sticks conveniently to the top of the casting and always within reach.

Hope somebody can find that useful, thanks for looking.

-frank

Like a lot of folks, I use a stick wax blade lubricant on the bandsaw. Comes in a cardboard tube about 2” in diameter and six inches long or so. I use Formax, but there are others, doesn’t matter. I like it, but always found the big tube awkward if I’m cutting something small. So I figured I’d downsize a bit.

Canada discontinued use of the copper penny a few years ago so I ended up with a surplus of paper coin rolling tubes. Turns out they are the exact same diameter as an electrical box knockout (everybody saves those, right?). So I poked one knockout down to the bottom of an empty tube, melted some chips of the Formax in an old tin can and poured in a half-inch or so. In a few minutes it was solid enough to pour the rest of the tube full and let it cool.

In use it works just like a crayon and I can get in close while the cut is in progress. And with the addition of a tiny magnet on the bottom of the knockout, it sticks conveniently to the top of the casting and always within reach.

Hope somebody can find that useful, thanks for looking.

-frank

Few people use cash anymore anyways, even the parking meter accepts a credit card.

Few people use cash anymore anyways, even the parking meter accepts a credit card.