-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threading

- Thread starter redvan22

- Start date

- Joined

- Jan 2, 2014

- Messages

- 9,349

There are some great PDF books hosted here.....

Atlas Manual of Lathe Operation(MOLO) and Machinists Tables 23rd edition 1967

SB How To Run a Lathe - 1966 27th Edition (56).pdf

-brino

Atlas Manual of Lathe Operation(MOLO) and Machinists Tables 23rd edition 1967

SB How To Run a Lathe - 1966 27th Edition (56).pdf

-brino

- Joined

- May 4, 2019

- Messages

- 817

WARNING

The books described above are excellent resources. The angle markings on these lathes were set at 0 when the compound was perpendicular to the ways. Many modern lathes have graduations where 0 sets the compound parallel with the ways. If you set 29* on most newer lathes you are going to be cutting bad threads. 59* is the equivalent of 29* on the old lathes.

The reason for a specific angle is so the infeed of the compound is approximately parallel to the trailing flank of the threading tool. The 29* or29.5* settings (on older lathes) is so the trailing flank of the tool takes a minute cut. That eliminates ridges in the flank of the thread.

If you prefer to plunge feed instead of flank feed it make no difference how the compound is set.

The books described above are excellent resources. The angle markings on these lathes were set at 0 when the compound was perpendicular to the ways. Many modern lathes have graduations where 0 sets the compound parallel with the ways. If you set 29* on most newer lathes you are going to be cutting bad threads. 59* is the equivalent of 29* on the old lathes.

The reason for a specific angle is so the infeed of the compound is approximately parallel to the trailing flank of the threading tool. The 29* or29.5* settings (on older lathes) is so the trailing flank of the tool takes a minute cut. That eliminates ridges in the flank of the thread.

If you prefer to plunge feed instead of flank feed it make no difference how the compound is set.

- Joined

- Aug 15, 2013

- Messages

- 2,522

Correction... 61* is the equivalent of 29* on some compound protractors.WARNING

........ 59* is the equivalent of 29* on the old lathes.

Tom

- Joined

- Aug 23, 2014

- Messages

- 932

The mini lathe is made for 8mm or 5/16" bits with the standard tool post . Anything larger needs a QCTP and holders. Smaller tools(1/4") will need to be shimmed about .125" for use with the standard tool post. Even 5/16" tools may need small shims to get them to center. A cheap automotive feeler gauge set works great as shim stock.

If you are not good at grinding tools it may be best to purchase pre-ground tools. This will let you start threading using a properly ground tool which will help eliminate one source of trouble. It also gives you a good example of how to grind your own. A center gauge is also needed to square the tool with the work. The machinists here may know of an other way to do this. Some tools that are not expensive:

Threading Tool Bit and Center Gage $16.95

littlemachineshop.com

littlemachineshop.com

Tool Bit, 5/16" HSS Threading $8.95

littlemachineshop.com

littlemachineshop.com

Some expensive tools:

Turning & Boring Tools, 5/16" Indexable, Triangle Inserts $79.95

littlemachineshop.com

littlemachineshop.com

Also A.R.Warner tools are great but expensive. You can find them at the little machine shop.

You can thread using the tool post at 0° instead of 29° as most machinists do. The mini lathe does not do 29 or 29.5° without some hassle. The angle is from parallel with the ways but that is not how the mini lathe reads. It shows 0° as perpendicular to the ways. It can be confusing to us beginners so going in at 0° is easiest at first. The mini would need to be set to 61° but it does not have a gauge for that.

Hopefully these few bits of info will help you get started along with the excellent tips given by the experienced machinists above.

Once you cut your first thread you will get a great feeling of accomplishment and you will inspire yourself to learn more and more operations.

Roy

If you are not good at grinding tools it may be best to purchase pre-ground tools. This will let you start threading using a properly ground tool which will help eliminate one source of trouble. It also gives you a good example of how to grind your own. A center gauge is also needed to square the tool with the work. The machinists here may know of an other way to do this. Some tools that are not expensive:

Threading Tool Bit and Center Gage $16.95

Threading Tool Bit and Center Gage 4115

Lathe Threading 4115 5/16" HSS Threading Tool Bit; 60 Degree Center Gage; The threading tool bit is sharpened on both ends to a 60° angle for threadi...

Tool Bit, 5/16" HSS Threading $8.95

Tool Bit, 5/16" HSS Threading 2221

Lathe Threading 2221 The 5/16" High Speed Steel Tool Bit Blank is a versatile and essential tool for any metal lathe operator. Made from high speed st...

Some expensive tools:

Turning & Boring Tools, 5/16" Indexable, Triangle Inserts $79.95

Turning & Boring Tools, 5/16" Indexable, Triangle Inserts 5432

Turning Tools 5432 4 turning tools; 1 boring tool; Inserts and torx wrenches; 5/16" shank; Uses TCMT-1.81.51 Inserts; Set comes in a fitted aluminum c...

Also A.R.Warner tools are great but expensive. You can find them at the little machine shop.

You can thread using the tool post at 0° instead of 29° as most machinists do. The mini lathe does not do 29 or 29.5° without some hassle. The angle is from parallel with the ways but that is not how the mini lathe reads. It shows 0° as perpendicular to the ways. It can be confusing to us beginners so going in at 0° is easiest at first. The mini would need to be set to 61° but it does not have a gauge for that.

Hopefully these few bits of info will help you get started along with the excellent tips given by the experienced machinists above.

Once you cut your first thread you will get a great feeling of accomplishment and you will inspire yourself to learn more and more operations.

Roy

- Joined

- May 4, 2019

- Messages

- 817

I hate it when I make stupid blunders.

- Joined

- Aug 23, 2014

- Messages

- 932

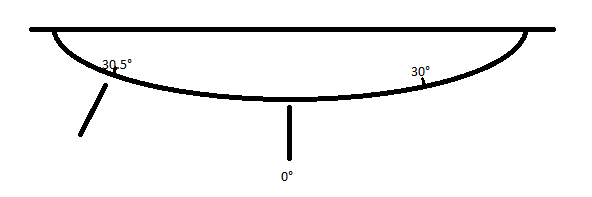

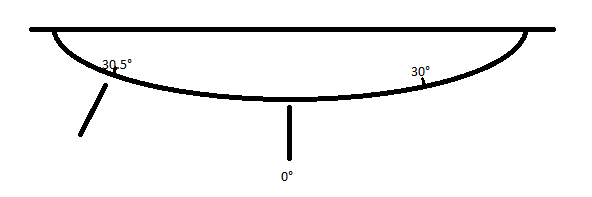

There is one way to use the the angle gauge on the mini lathe to do 29.5° . The gauge is marked for 40° in each direction. Make an index mark at the 30.5° degree indication on the left of the 0° point. Now turn the tool post clockwise so that the 30° mark on the right side of the 0° mark is aligned with the 30.5° mark you made. This should give you 29.5° from perpendicular to the spindle center line. Thanx Tom for the correction.

Also make sure that all gibs are adjusted properly. Any slop or movement of the carriage, cross slide or compound lets the tool move and can cause chatter.

Another tool you will need is a screw pitch gauge. Both fractional and metric.

It is good to use an aluminum or acetel rod for your first single point threading try. Home Depot, Lowe's and Ace in my area sell 1/4",3/8" and 1/2" aluminum rod in 3 foot lengths. I used 1/2" x 13TPI for my first try. Use a matching nut to test fit your threads. Use a slow rpm, under 100 rpm and maybe make .010" deep cuts until you can screw the nut on. As you get closer the cuts can be smaller. This is a small and not very rigid lathe and small cuts are better.

Make a relief cut on the rod where you want the threads to end. Depth should be about the same as the base diameter of the threads.

Using the threading dial is not necessary. You can stop the spindle with the motor power switch at the end of the thread, remember where the compound was set then back off the compound to clear the work and then reverse the motor to go back past the start of the threads. Stop the motor, put the reversing switch in forward position. Then set the compound for about .005" to .010" depth past where it was. Now turn on the motor and make another cut. ALL this is done with the half nuts engaged. If you disengage the half nuts at any point the threads will be ruined unless you can engage the half nuts in exactly the same place.

Roy

Also make sure that all gibs are adjusted properly. Any slop or movement of the carriage, cross slide or compound lets the tool move and can cause chatter.

Another tool you will need is a screw pitch gauge. Both fractional and metric.

It is good to use an aluminum or acetel rod for your first single point threading try. Home Depot, Lowe's and Ace in my area sell 1/4",3/8" and 1/2" aluminum rod in 3 foot lengths. I used 1/2" x 13TPI for my first try. Use a matching nut to test fit your threads. Use a slow rpm, under 100 rpm and maybe make .010" deep cuts until you can screw the nut on. As you get closer the cuts can be smaller. This is a small and not very rigid lathe and small cuts are better.

Make a relief cut on the rod where you want the threads to end. Depth should be about the same as the base diameter of the threads.

Using the threading dial is not necessary. You can stop the spindle with the motor power switch at the end of the thread, remember where the compound was set then back off the compound to clear the work and then reverse the motor to go back past the start of the threads. Stop the motor, put the reversing switch in forward position. Then set the compound for about .005" to .010" depth past where it was. Now turn on the motor and make another cut. ALL this is done with the half nuts engaged. If you disengage the half nuts at any point the threads will be ruined unless you can engage the half nuts in exactly the same place.

Roy

Last edited: