- Joined

- Oct 6, 2010

- Messages

- 699

I have been gathering materials and tools for an upcoming project - making a 2 1/4 OD x 6 thread/inch plug gauge so that I can make a chuck adapter plate for an old 14 1/2 inch South Bend lathe. I read that the triangles are easier to use but the wires are more accurate. I found a set of thread triangles on Craigslist at a fair price so I got them. The seller had a set of wires also so I got them too.

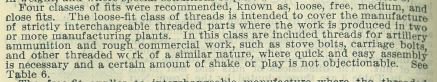

The triangles came with a chart for the common threads from #0 through 1 1/2 inch nominal sizes along with the formula for use to find the measurements for other or special threads. The chart or container does not have a manufacturers name on them so I suspect they are import. The included chart says in the heading “Simmons Equivalents as measured over triangles". A search on the name "Simmons" found the following patent: http://www.google.com/patents/US2466490 this is interesting but not likely the manufacturer.

I have made a PDF file of the written information included with the tread triangles and can provide that if anyone is interested. However in my searches I read that included charts for thread triangle vary with manufacturer. Not sure if this is true or not.

For my use the thread triangles being import does not bother me but what does raise a question is in the formula instructions a class 4 fit (highlighted in picture below) is mentioned. I am not sure what that means. The included charts only mention classes 2, 2a, 3, and 3a.

View attachment 60574

Does anyone know what the “class 4 fit” means?

Benny

The Orphanage Never Closes

The triangles came with a chart for the common threads from #0 through 1 1/2 inch nominal sizes along with the formula for use to find the measurements for other or special threads. The chart or container does not have a manufacturers name on them so I suspect they are import. The included chart says in the heading “Simmons Equivalents as measured over triangles". A search on the name "Simmons" found the following patent: http://www.google.com/patents/US2466490 this is interesting but not likely the manufacturer.

I have made a PDF file of the written information included with the tread triangles and can provide that if anyone is interested. However in my searches I read that included charts for thread triangle vary with manufacturer. Not sure if this is true or not.

For my use the thread triangles being import does not bother me but what does raise a question is in the formula instructions a class 4 fit (highlighted in picture below) is mentioned. I am not sure what that means. The included charts only mention classes 2, 2a, 3, and 3a.

View attachment 60574

Does anyone know what the “class 4 fit” means?

Benny

The Orphanage Never Closes