Hello,

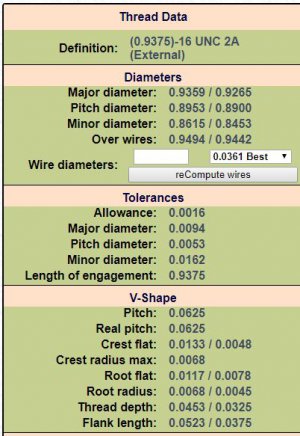

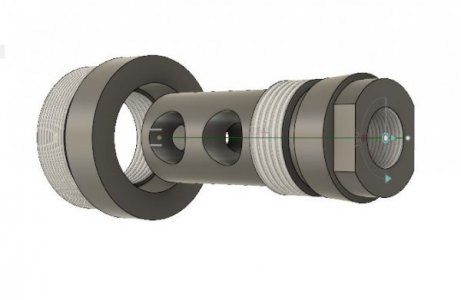

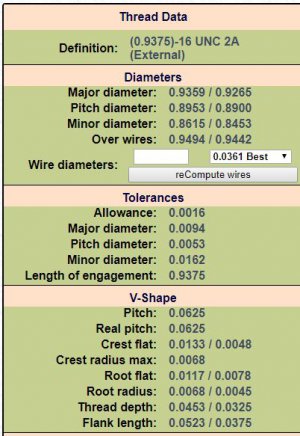

I am a fairly new to machining and even newer to a lathe. I have a G0602 10x22 lathe and I need to machine an endcap to fit on to a previously made brake (for a forum 1 suppressor build). I have 2 brakes made so far, i checked the pitch diameter with wires while threading the brake but they were very difficult to hold and get a good reading. I have a thread mic coming tomorrow that i'll be able to get the exact pitch diameter. But I have not internal threaded before and i've heard people say opposite things and i just want to grasp it more before i try it. I've watched alot of videos and read though quite a few threads on internal threading, and i have a couple questions that may be simple but I'm a newbie

Is the cross slide better for controlling depth than the compound for internal threading?

Once my thread mic comes and i get the exact pitch diameter can that help me for cutting the internal thread?

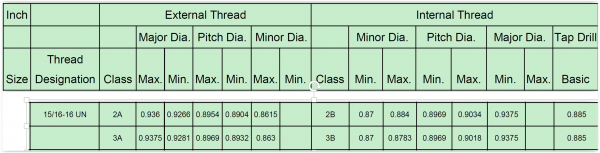

For pitch diameters there is around .005 tolerance is it better to be on the tighter or looser side?

Also for bore diameter for threading i know to use the minor diameter of the threads but once again there is .012 range to the minor

I am a fairly new to machining and even newer to a lathe. I have a G0602 10x22 lathe and I need to machine an endcap to fit on to a previously made brake (for a forum 1 suppressor build). I have 2 brakes made so far, i checked the pitch diameter with wires while threading the brake but they were very difficult to hold and get a good reading. I have a thread mic coming tomorrow that i'll be able to get the exact pitch diameter. But I have not internal threaded before and i've heard people say opposite things and i just want to grasp it more before i try it. I've watched alot of videos and read though quite a few threads on internal threading, and i have a couple questions that may be simple but I'm a newbie

Is the cross slide better for controlling depth than the compound for internal threading?

Once my thread mic comes and i get the exact pitch diameter can that help me for cutting the internal thread?

For pitch diameters there is around .005 tolerance is it better to be on the tighter or looser side?

Also for bore diameter for threading i know to use the minor diameter of the threads but once again there is .012 range to the minor