Hello hobby machinists!

I've been making changewheel charts, skip the next two paragraphs if that's all you're interested in.

I want to cut a 2BA thread on my ML7 because I'm finding the allen bolt which is used to engage and disengage the back-gear is turning out to be a nightmare to reach. The only way I can get to it with the allen keys I have means taking off the top of the near-chuck spindle bearing. I have thought about butchering my allen key to make it stubby enough to fit and I might still do that if nothing else works out but figured if I only need one hex-head bolt and I have stock for some other projects coming anyway I might as well give it a go if I come by an afternoon free. (If not I know I can just buy the bolts, annoying when you only want one though.)

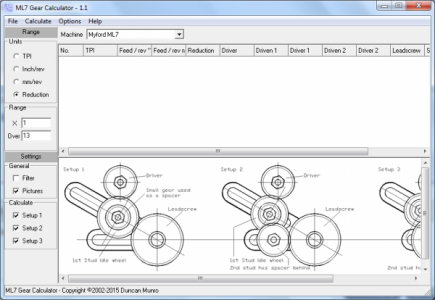

I've been having a look around and couldn't find anything much good in the way of changewheel charts for 2BA on an ML7, plus I have a really strange set of changewheels. I've been plugging away at the numbers and worked out a method for building the gear trains on pen and paper including a neat trick using prime factors to narrow down the search space, but since I need to cut an approximation to 2BA this is still a real pain. So I finally caved in and delegated the job to my PC.

My program computes every possible gear train ratio with the gears the user specifies and number of studs to mount them on (not counting any needed idler wheels) - remembers the gear trains required used to produce each ratio - calculates the thread pitch produced by each ratio - filters based on those pitches - sorts the pitches - then prints the pitches out with their gear trains to a file. I've included a few runs of the program which are applicable to my ML7 and set of gears: 20, 20, 25, 30, 35, 38, 40, 45, 50, 55, 60, 65, 70, 75.

The program is written in Python (3) which means you can open and tweak the parameters if you have a different set of changewheels or a different leadscrew. (And obviously a Python interpreter and the good sense to verify for yourself that the program isn't malware.)

The charts have no awareness of what's a good approximation to a useful thread or what's a garbage thread, so everything's included. This is useful because it tells you approximations, so you CAN cut metric threads without a 127 tooth gear, or at least threads that are close enough. To cut a 1.00mm pitch thread I would choose the 1-stud metric chart and scroll down to where the 0.9s meet the 1.0s and pick one of the gear trains either side of 1.0. I was really surprised to find that my 38-tooth gear cuts a less accurate metric thread than a (20x65 / 55x75) combination (0.061% error!). If none of the options on the 1-stud chart look good then you can always go to the 2-stud chart and see if there's something better there. With 3 studs the program might start to, err, strain, but it should come up with some really bizarre but accurate approximates where the correct changewheels aren't available.

For instance on my ML7 with my gears I can cut a metric 1.00mm pitch thread with 0.012% error if I use the gear train (30x35x45 / 40x50x75).

For all my searching I couldn't find a resource like this anywhere else online, I'm sure I can't be the first person to do this so have I re-invented the wheel? Where do you other members normally go looking for resources like rare pitch changewheel charts? Any opinions on error margins like 0.061%? I would have thought a 2% error was acceptable for most hobbyist work.

Any suggestions on what charts I could now derive from the universal chart? I'm aware of Whitworth, UNC, UNF, BA - any other charts in need of some more choices on any particular lathes out there?

I've been making changewheel charts, skip the next two paragraphs if that's all you're interested in.

I want to cut a 2BA thread on my ML7 because I'm finding the allen bolt which is used to engage and disengage the back-gear is turning out to be a nightmare to reach. The only way I can get to it with the allen keys I have means taking off the top of the near-chuck spindle bearing. I have thought about butchering my allen key to make it stubby enough to fit and I might still do that if nothing else works out but figured if I only need one hex-head bolt and I have stock for some other projects coming anyway I might as well give it a go if I come by an afternoon free. (If not I know I can just buy the bolts, annoying when you only want one though.)

I've been having a look around and couldn't find anything much good in the way of changewheel charts for 2BA on an ML7, plus I have a really strange set of changewheels. I've been plugging away at the numbers and worked out a method for building the gear trains on pen and paper including a neat trick using prime factors to narrow down the search space, but since I need to cut an approximation to 2BA this is still a real pain. So I finally caved in and delegated the job to my PC.

My program computes every possible gear train ratio with the gears the user specifies and number of studs to mount them on (not counting any needed idler wheels) - remembers the gear trains required used to produce each ratio - calculates the thread pitch produced by each ratio - filters based on those pitches - sorts the pitches - then prints the pitches out with their gear trains to a file. I've included a few runs of the program which are applicable to my ML7 and set of gears: 20, 20, 25, 30, 35, 38, 40, 45, 50, 55, 60, 65, 70, 75.

The program is written in Python (3) which means you can open and tweak the parameters if you have a different set of changewheels or a different leadscrew. (And obviously a Python interpreter and the good sense to verify for yourself that the program isn't malware.)

The charts have no awareness of what's a good approximation to a useful thread or what's a garbage thread, so everything's included. This is useful because it tells you approximations, so you CAN cut metric threads without a 127 tooth gear, or at least threads that are close enough. To cut a 1.00mm pitch thread I would choose the 1-stud metric chart and scroll down to where the 0.9s meet the 1.0s and pick one of the gear trains either side of 1.0. I was really surprised to find that my 38-tooth gear cuts a less accurate metric thread than a (20x65 / 55x75) combination (0.061% error!). If none of the options on the 1-stud chart look good then you can always go to the 2-stud chart and see if there's something better there. With 3 studs the program might start to, err, strain, but it should come up with some really bizarre but accurate approximates where the correct changewheels aren't available.

For instance on my ML7 with my gears I can cut a metric 1.00mm pitch thread with 0.012% error if I use the gear train (30x35x45 / 40x50x75).

For all my searching I couldn't find a resource like this anywhere else online, I'm sure I can't be the first person to do this so have I re-invented the wheel? Where do you other members normally go looking for resources like rare pitch changewheel charts? Any opinions on error margins like 0.061%? I would have thought a 2% error was acceptable for most hobbyist work.

Any suggestions on what charts I could now derive from the universal chart? I'm aware of Whitworth, UNC, UNF, BA - any other charts in need of some more choices on any particular lathes out there?

Attachments

-

my_universal_chart_tpi_idleonly.txt2.1 KB · Views: 41

-

my_universal_chart_tpi_1stud.txt71.8 KB · Views: 10

-

my_universal_chart_tpi_2stud.txt663 KB · Views: 9

-

my_universal_chart_metric_idleonly.txt511 bytes · Views: 6

-

my_universal_chart_metric_1stud.txt23.9 KB · Views: 10

-

my_universal_chart_metric_2stud.txt265.5 KB · Views: 6

-

universal_gear_chart.py.txt5.1 KB · Views: 14