- Joined

- Oct 13, 2014

- Messages

- 9,497

Well, sort of...

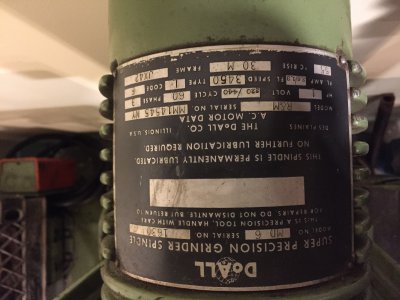

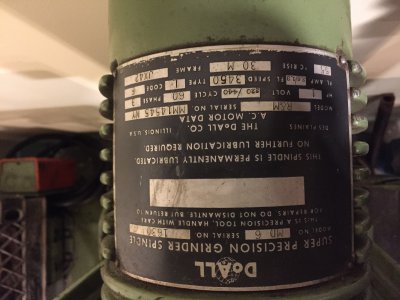

A few weeks ago, when I was making preparations to move my newly acquired Mill from the dealer to my newly forming machine shop, I figured I would troll Craigslist and see if there were any good deals on other machines. After all, if I was renting a truck I might as well fill it up I was hoping for a nice 13x40 lathe but sadly there were none available, Then I found a DoAll DH612 Surface Grinder with hydraulic drive, electromagnetic chuck and some other tooling for $500, and it was located (kind of) of between the mill dealer and my shop...

I was hoping for a nice 13x40 lathe but sadly there were none available, Then I found a DoAll DH612 Surface Grinder with hydraulic drive, electromagnetic chuck and some other tooling for $500, and it was located (kind of) of between the mill dealer and my shop...

I called the guy, a machinist who had bought the machine from the pharmaceutical company he had worked for. He told me the machine had seen little use in the 20 years he worked there. I asked him how easy it wold be to load the grinder onto the truck as I would be traveling solo, he said, "You can back a truck right to the door" he added that he had a broken foot thus couldn't be of much help but he had loaded the grinder into his shop by himself, so it shouldn't be a problem...

The day of the move started out bad. The rental company didn't have the 16' lift-gate truck I reserved as the previous customer hadn't yet returned it. However, there was a 26 footer, at another location "only" 11.5 miles away (that's an hour and a half in NYC travel time). So by the time I get the truck and get to the Mill dealer, I was a full 3 hrs behind schedule. Fortunately, the they had the Mill all ready for me and forklifted it right into the truck, I was out of there in 20 min... I had called the Grinder guy earlier and left a message explaining the larger truck and he should call me immediately if he thought it would be a problem, I never heard back so I figured it was on. When I arrived at his house it was immediately apparent there was no way I would be able to "back the truck right to the door". The said door was around the back of the house, had no paved access, and the house was on a pretty steep grade with only a narrow "level" border. So not even if I had the smaller truck would it have been possible, at least not without destroying the guys lawn and running the risk of rolling the truck. I thought it wasn't going to happen but I don't give up easily...

The guy had a shop crane and some dollies so I was able to get the grinder to the door without too much trouble... The machine is very top heavy, while trying to get it through the door it started to flip over, it was then almost horizontal, halfway through the door and what was worse, the sling that was holding it was about to slip off... A few minutes of impending wretchedness passed as I managed to secure another sling around the machine, while trying to stay clear of the "crush zone". I then started to lower the ram on the shop crane and the first sling slipped. Fortunately, the second one held and the grinder was unharmed. On the positive side, the mishap revealed the top of the machine was not bolted to the base which , upon separating them made it easier to move, as the heaviest part was then lower to the ground and now outside the door. The guy had a small ATV trailer and his idea was that we could use it to transport the grinder from the door to the truck, he thought we could push it up the wheel ramp, perhaps if we had a couple of more hands to help but there was no way I and he (with a broken foot) would have been able to push that 800+ pound machine up the ramp. Then I remembered I had brought an electric winch with me ( yes, I had totally forgotten about it till that moment), we managed to rig it to the front of the trailer and started to pull the grinder up the ramp, after a couple of feet, it slipped off... The lawn was soft and there was no damage, so we moved the trailer forward, re-rigged and finally got the grinder on the trailer. I was the able to pull the trailer and hitch it to his SUV. Of course there was another brief moment of mild panic when one of the dolly whees the machine was on, slipped into the gap between the trailer and the lift-gate of the truck. Quick application the johnson bar saved that one. It took three and a half hours but the grinder was mine. The unloading of the two machines at night was another bit of drama but that's another story...

Yesterday. I took a break from setting up the mill and got the grinder temporally hooked up and running, you know, just to see where its at.

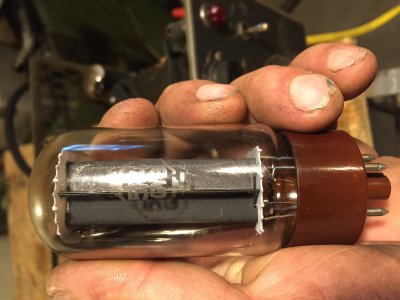

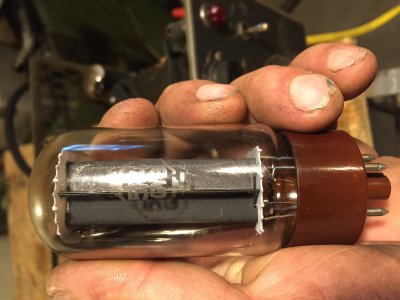

To my surprise the vacuum tube equipped electromagnetic chuck controller still works and the ways appear to be worn pretty evenly. I ground a couple of test pieces, the finish not great the but the flatness was within five tenths, which I feel is not bad considering it isn't properly set up yet, the chuck hasn't been ground in, the wheel hasn't been balanced, etc. The machine will need a partial teardown, through cleaning and adjusting. Unfortunately

I won't be able to get to that for a while....

I won't be able to get to that for a while....

A few weeks ago, when I was making preparations to move my newly acquired Mill from the dealer to my newly forming machine shop, I figured I would troll Craigslist and see if there were any good deals on other machines. After all, if I was renting a truck I might as well fill it up

I called the guy, a machinist who had bought the machine from the pharmaceutical company he had worked for. He told me the machine had seen little use in the 20 years he worked there. I asked him how easy it wold be to load the grinder onto the truck as I would be traveling solo, he said, "You can back a truck right to the door" he added that he had a broken foot thus couldn't be of much help but he had loaded the grinder into his shop by himself, so it shouldn't be a problem...

The day of the move started out bad. The rental company didn't have the 16' lift-gate truck I reserved as the previous customer hadn't yet returned it. However, there was a 26 footer, at another location "only" 11.5 miles away (that's an hour and a half in NYC travel time). So by the time I get the truck and get to the Mill dealer, I was a full 3 hrs behind schedule. Fortunately, the they had the Mill all ready for me and forklifted it right into the truck, I was out of there in 20 min... I had called the Grinder guy earlier and left a message explaining the larger truck and he should call me immediately if he thought it would be a problem, I never heard back so I figured it was on. When I arrived at his house it was immediately apparent there was no way I would be able to "back the truck right to the door". The said door was around the back of the house, had no paved access, and the house was on a pretty steep grade with only a narrow "level" border. So not even if I had the smaller truck would it have been possible, at least not without destroying the guys lawn and running the risk of rolling the truck. I thought it wasn't going to happen but I don't give up easily...

The guy had a shop crane and some dollies so I was able to get the grinder to the door without too much trouble... The machine is very top heavy, while trying to get it through the door it started to flip over, it was then almost horizontal, halfway through the door and what was worse, the sling that was holding it was about to slip off... A few minutes of impending wretchedness passed as I managed to secure another sling around the machine, while trying to stay clear of the "crush zone". I then started to lower the ram on the shop crane and the first sling slipped. Fortunately, the second one held and the grinder was unharmed. On the positive side, the mishap revealed the top of the machine was not bolted to the base which , upon separating them made it easier to move, as the heaviest part was then lower to the ground and now outside the door. The guy had a small ATV trailer and his idea was that we could use it to transport the grinder from the door to the truck, he thought we could push it up the wheel ramp, perhaps if we had a couple of more hands to help but there was no way I and he (with a broken foot) would have been able to push that 800+ pound machine up the ramp. Then I remembered I had brought an electric winch with me ( yes, I had totally forgotten about it till that moment), we managed to rig it to the front of the trailer and started to pull the grinder up the ramp, after a couple of feet, it slipped off... The lawn was soft and there was no damage, so we moved the trailer forward, re-rigged and finally got the grinder on the trailer. I was the able to pull the trailer and hitch it to his SUV. Of course there was another brief moment of mild panic when one of the dolly whees the machine was on, slipped into the gap between the trailer and the lift-gate of the truck. Quick application the johnson bar saved that one. It took three and a half hours but the grinder was mine. The unloading of the two machines at night was another bit of drama but that's another story...

Yesterday. I took a break from setting up the mill and got the grinder temporally hooked up and running, you know, just to see where its at.

To my surprise the vacuum tube equipped electromagnetic chuck controller still works and the ways appear to be worn pretty evenly. I ground a couple of test pieces, the finish not great the but the flatness was within five tenths, which I feel is not bad considering it isn't properly set up yet, the chuck hasn't been ground in, the wheel hasn't been balanced, etc. The machine will need a partial teardown, through cleaning and adjusting. Unfortunately

I won't be able to get to that for a while....

I won't be able to get to that for a while....

Last edited: