- Joined

- Jul 13, 2014

- Messages

- 1,054

For your reading enjoyment here is a little lathe that just might could. Ulma Doctor sourced this jewel from his AO and it is heading to TX soon. This is the Taiwanese made Jet 1024P, a smallish, but stout for its size. There are a couple of broken parts, but nothing of significance, the left change lever and the TS hand wheel.

The spec is pretty decent for a little guy, 7 3/8 bed width is not that far behind some of the current offerings of larger swing, the PM1340GT at 7 1/2 for example.

To start off, here are some pictures of the lathe.

Below shows the initial evaluation by Mike

"Here's some more pix of the 1024

i mounted a tenth's indicator on the saddle and swept the x, there was a .0001" dip about 8" from the headstock

i inspected the cross slide ways, there is still original scraping seen on over 85% of the surfaces

i lubed the spindle pulley bushings,gearing &,oil points

i ran the lathe for about 20 mins both in thread cutting mode as well as fine feed modes.

it sounds like an angel singing, especially when there is no gearbox feed engagement- you can't barely hear it run- it whispers

i did find another minor defect, the PO drilled and tapped 2 holes in the cross slide above the dovetails- for what purpose i don't know.

i may put set screws or allen screws to close them up as swarf could enter- not a big deal

overall the lathe is what i'd call sweet!

all the best mike"

Followed up with a test bar

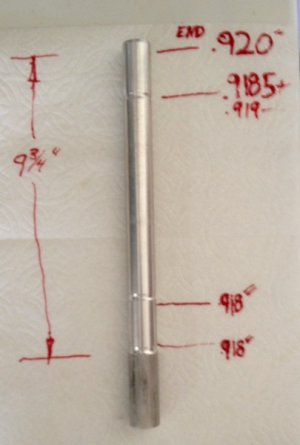

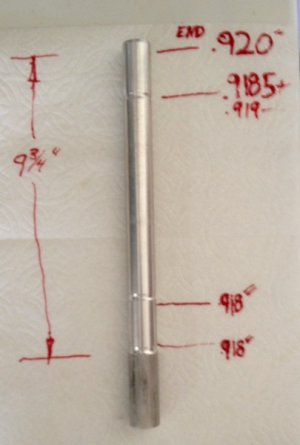

"i made a test bar

there was a lot of chatter the first time with a pointed bit, so i did it a second time with a rounded tool bit.

near the chuck i got .918"

an inch + away from the chuck i got .918"

at about 8" from the chuck i got .919"(rounded up)

at the very end, almost 10" away from the chuck, i got .920" with slight chatter

to be fair, i took an extra spring cut on the far end test pad.

other than that all things were equal during the test sequence, cut dry.

i'll include the test bar with the lathe when i send it.

all in all i'd say very good for an unmounted lathe with nearly 10" of hang out

whaddya think?"

I honestly believe when I get this lathe going, it will give me years of good service. If you factor in how the taper test was performed, the lathe unbolted, and sitting on a pile of wood, and get a thou across 8 inches, that is awesome. Mike's initial evaluation was validated by this test.

In preparation for the lathe arrival and installation, I already bought a Hitachi WJ200 VFD, MKSJ's favorite and his recommendation, got a good deal on a 2 HP Marathon Inverter Motor for $125 and local pick up, and lastly, coming is a 50 ohm, 500 Watt break resistor. The VFD control system will have the usual Mark's whiz bang creation. Mark, thank you in advance.

This is the same lathe featured in this thread.

http://www.hobby-machinist.com/threads/how-to-remove-a-3-jaw-chuck.48288/#post-407939

Mike, Thank you so much for finding this jewel and thank for your all your help.

The spec is pretty decent for a little guy, 7 3/8 bed width is not that far behind some of the current offerings of larger swing, the PM1340GT at 7 1/2 for example.

To start off, here are some pictures of the lathe.

Below shows the initial evaluation by Mike

"Here's some more pix of the 1024

i mounted a tenth's indicator on the saddle and swept the x, there was a .0001" dip about 8" from the headstock

i inspected the cross slide ways, there is still original scraping seen on over 85% of the surfaces

i lubed the spindle pulley bushings,gearing &,oil points

i ran the lathe for about 20 mins both in thread cutting mode as well as fine feed modes.

it sounds like an angel singing, especially when there is no gearbox feed engagement- you can't barely hear it run- it whispers

i did find another minor defect, the PO drilled and tapped 2 holes in the cross slide above the dovetails- for what purpose i don't know.

i may put set screws or allen screws to close them up as swarf could enter- not a big deal

overall the lathe is what i'd call sweet!

all the best mike"

Followed up with a test bar

"i made a test bar

there was a lot of chatter the first time with a pointed bit, so i did it a second time with a rounded tool bit.

near the chuck i got .918"

an inch + away from the chuck i got .918"

at about 8" from the chuck i got .919"(rounded up)

at the very end, almost 10" away from the chuck, i got .920" with slight chatter

to be fair, i took an extra spring cut on the far end test pad.

other than that all things were equal during the test sequence, cut dry.

i'll include the test bar with the lathe when i send it.

all in all i'd say very good for an unmounted lathe with nearly 10" of hang out

whaddya think?"

I honestly believe when I get this lathe going, it will give me years of good service. If you factor in how the taper test was performed, the lathe unbolted, and sitting on a pile of wood, and get a thou across 8 inches, that is awesome. Mike's initial evaluation was validated by this test.

In preparation for the lathe arrival and installation, I already bought a Hitachi WJ200 VFD, MKSJ's favorite and his recommendation, got a good deal on a 2 HP Marathon Inverter Motor for $125 and local pick up, and lastly, coming is a 50 ohm, 500 Watt break resistor. The VFD control system will have the usual Mark's whiz bang creation. Mark, thank you in advance.

This is the same lathe featured in this thread.

http://www.hobby-machinist.com/threads/how-to-remove-a-3-jaw-chuck.48288/#post-407939

Mike, Thank you so much for finding this jewel and thank for your all your help.

Attachments

Last edited: