- Joined

- Jun 23, 2016

- Messages

- 30

The short of it is that I purchased a lathe with a bent spindle (.0015" out). I was able to find a replacement spindle after removing the original to confirm the location of the bend.

Any ideas on how to remove this precision bearing without damaging it?

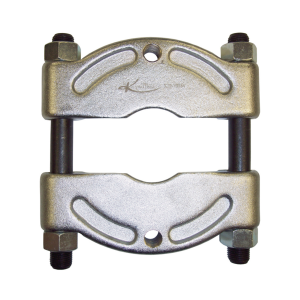

I was thinking of packing the spindle with dry ice, and taking a rosebud tip from on oxy/acetylene setup to heat up the inner race. Then use a bearing splitter/puller. I'm a little worried about damaging the cage though.

I would really appreciate any input you guys have. Thanks again!

Any ideas on how to remove this precision bearing without damaging it?

I was thinking of packing the spindle with dry ice, and taking a rosebud tip from on oxy/acetylene setup to heat up the inner race. Then use a bearing splitter/puller. I'm a little worried about damaging the cage though.

I would really appreciate any input you guys have. Thanks again!