- Joined

- Aug 3, 2017

- Messages

- 2,437

SO I was on craigslist or something the other day, and found a lathe that is just like mine! I looked at the pictures and I saw this:

That is a picture of the taper attachment, which I have. HOWEVER, the knob assembly on the left is something I'd never seen before! I ran out to my lathe to take a look, and saw this:

You'll see that I have the hole in the top-part, and a bolt in the bottom part (right side). I unscrewed the bolt just to find out that the threads were made out of muck! Turns out I have the holes, and someone lost the fine-adjust assembly before I bought it.

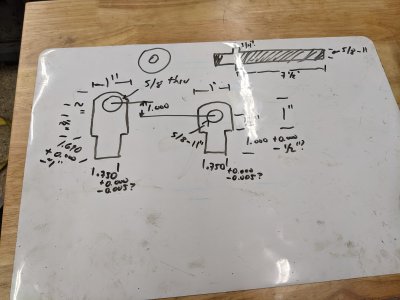

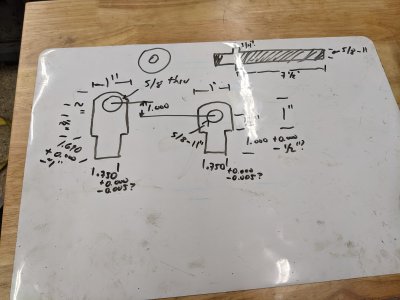

Next step, was to sketch my plan with important measurements. I found that the holes were .750 each, and there was a 1" elevation difference. I chose 5/8-11 for the thread, since it is the largest tap I have. I considered a thread that divided better, but based on how rarely I use this taper attachment, and how it tends to be 'measure off an existing thing', I didn't think I would ever use the thread to measure anything so much as just turn slowly. I figure I can up-size to a 3/4-20 or something later if I find it necessary.

I started with the smaller part. I had a scrap of 1" 12L14 that worked perfect for this one. I turned it down to a touch less than 1", and made a just-less-than-1" stub on the end.

I put it in my mill to cross-drill and tap. The tapping was a giant pain, and the threads-out-the-side of the arc were awful, so I also ran a mill across both sides. I don't know if I capture it, but it DID manage to slip in my 5c collet at one point so one side is a little mangled, but not enough to change function. Plus, its on the back of the lathe

Back in the lathe, I turned off the extra material and rounded over the end.

Starting on the next part, I had a 1.5" 12L14 that I had to turn a bunch off of and do the same lathe work as above, just a little longer. The top is an inch taller, the bottom is closer to 1.5", since I have that much room (and more!).

A quick trip to the bandsaw saves me removal later:

I cross-drilled clearance for 5/8" here. I ended up having to use my boring head, since I had no matching drill bit. However, in retrospect, there is no reason this side needs to be 5/8". I have the threaded rod designed with a shoulder on one side, and the knob holding it in place on the other, so in retrospect I could have made this something that would have let me use a washer + all-thread. Oh well, looks like I have to single point (I need the practice for the dividing head anyway!).

I milled flats on both sides to deal with the shoulders later. I finally got to use my planer gauge!

And the two parts finished and in place! Just the threaded rod (I ordered some 12L14 for it) plus the knob left. I have a little more engineering on how to attach the knob correctly. I've considered threading the back attachment for it then loctiting the knob in place, or a taper pin, or just a set-screw. I guess I'll have to think about it!

That is a picture of the taper attachment, which I have. HOWEVER, the knob assembly on the left is something I'd never seen before! I ran out to my lathe to take a look, and saw this:

You'll see that I have the hole in the top-part, and a bolt in the bottom part (right side). I unscrewed the bolt just to find out that the threads were made out of muck! Turns out I have the holes, and someone lost the fine-adjust assembly before I bought it.

Next step, was to sketch my plan with important measurements. I found that the holes were .750 each, and there was a 1" elevation difference. I chose 5/8-11 for the thread, since it is the largest tap I have. I considered a thread that divided better, but based on how rarely I use this taper attachment, and how it tends to be 'measure off an existing thing', I didn't think I would ever use the thread to measure anything so much as just turn slowly. I figure I can up-size to a 3/4-20 or something later if I find it necessary.

I started with the smaller part. I had a scrap of 1" 12L14 that worked perfect for this one. I turned it down to a touch less than 1", and made a just-less-than-1" stub on the end.

I put it in my mill to cross-drill and tap. The tapping was a giant pain, and the threads-out-the-side of the arc were awful, so I also ran a mill across both sides. I don't know if I capture it, but it DID manage to slip in my 5c collet at one point so one side is a little mangled, but not enough to change function. Plus, its on the back of the lathe

Back in the lathe, I turned off the extra material and rounded over the end.

Starting on the next part, I had a 1.5" 12L14 that I had to turn a bunch off of and do the same lathe work as above, just a little longer. The top is an inch taller, the bottom is closer to 1.5", since I have that much room (and more!).

A quick trip to the bandsaw saves me removal later:

I cross-drilled clearance for 5/8" here. I ended up having to use my boring head, since I had no matching drill bit. However, in retrospect, there is no reason this side needs to be 5/8". I have the threaded rod designed with a shoulder on one side, and the knob holding it in place on the other, so in retrospect I could have made this something that would have let me use a washer + all-thread. Oh well, looks like I have to single point (I need the practice for the dividing head anyway!).

I milled flats on both sides to deal with the shoulders later. I finally got to use my planer gauge!

And the two parts finished and in place! Just the threaded rod (I ordered some 12L14 for it) plus the knob left. I have a little more engineering on how to attach the knob correctly. I've considered threading the back attachment for it then loctiting the knob in place, or a taper pin, or just a set-screw. I guess I'll have to think about it!