- Joined

- Nov 8, 2020

- Messages

- 46

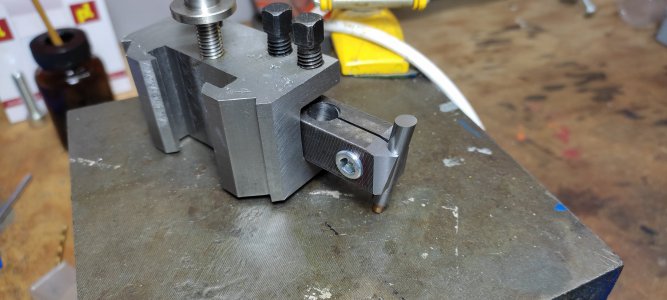

Tangential Toolholders with square and round toolbits for the lathe have been on my list for quite some time know. I started out with the easier one for round toolbits. Everything was made out of stuff I already had around... An old toolholder and broken carbide endmills, out of which the toolbits will be ground.

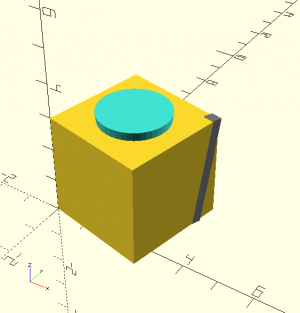

I decided to go with 6mm endmills. Tangential toolholders for square toolbits are tilted in two planes to clear the edges. For this round one I only tilted it 12° in one plane, away from the work. I figured in my head I should be able to achive the tilt of the other plane by rotating the bit in the toolholder - I hope I'll be correct on that.

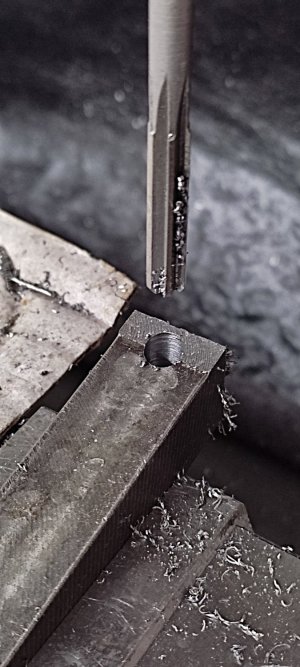

So I tilted the toolholder 12° in the vise, spotmilled, drilled and reamed for 6mm.

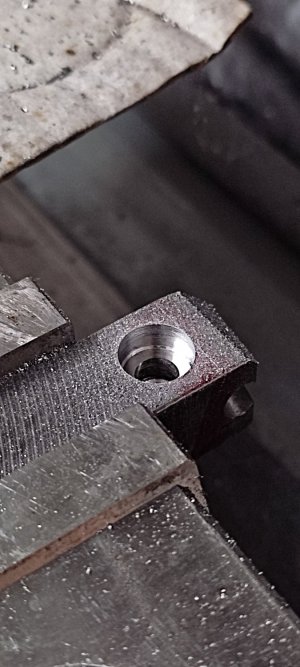

Next reliefed the bore for the clamping to work and all the clearance angles around the toolbit.

The last things were to drill, counterbore and thread for M6 aswell as slitting the holder.

By the way I now have the proper Machine to do the grinding

So there it is. I'll hand in some images of surface finish after turning later, once I've put this to use and figured the right cutting parameters out.

I decided to go with 6mm endmills. Tangential toolholders for square toolbits are tilted in two planes to clear the edges. For this round one I only tilted it 12° in one plane, away from the work. I figured in my head I should be able to achive the tilt of the other plane by rotating the bit in the toolholder - I hope I'll be correct on that.

So I tilted the toolholder 12° in the vise, spotmilled, drilled and reamed for 6mm.

Next reliefed the bore for the clamping to work and all the clearance angles around the toolbit.

The last things were to drill, counterbore and thread for M6 aswell as slitting the holder.

By the way I now have the proper Machine to do the grinding

So there it is. I'll hand in some images of surface finish after turning later, once I've put this to use and figured the right cutting parameters out.