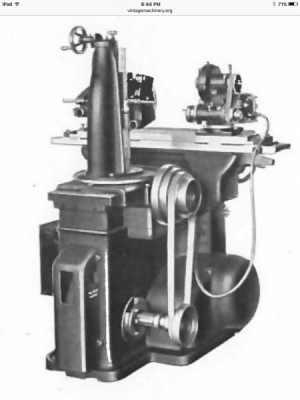

I am refurbing a B&S #13 universal grinder, built around 1940. It has a flat belt cone pulley system to drive the table. The lower cone pulley is missing. I have searched internet and manuals for the pulley sizes, haven't been able to find it. I found a pic in a manual but it doesn't give sizes.

If no one knows the sizes, maybe someone can tell me how to calculate them from the parts I have. I have upper cone pulley, and the belt that parts manual listed and of course the center to center distances.

I have a Machinery's Handbook but I can't seem to find what I need. It tells pulley sizes for rpm, belt length needed etc.

Any help will be much appreciated.

Thanks

Chuck

If no one knows the sizes, maybe someone can tell me how to calculate them from the parts I have. I have upper cone pulley, and the belt that parts manual listed and of course the center to center distances.

I have a Machinery's Handbook but I can't seem to find what I need. It tells pulley sizes for rpm, belt length needed etc.

Any help will be much appreciated.

Thanks

Chuck