- Joined

- Mar 26, 2018

- Messages

- 8,666

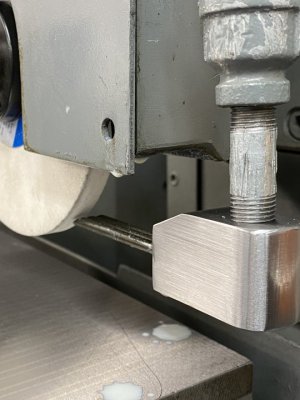

I’ve seen these nozzles on Tom Lipton’s channel and Mr. Renzetti’s.

It’s my attempt to provide coolant where I need it without constantly fiddling with those plastic wobbly things.

The frame is easily adjustable vertically and horizontally.

The tubing is break line. Something I am very familiar with.

It’s my attempt to provide coolant where I need it without constantly fiddling with those plastic wobbly things.

The frame is easily adjustable vertically and horizontally.

The tubing is break line. Something I am very familiar with.

Attachments

-

C75E1183-0B63-47DA-9E4C-E5E2D9DE3586.jpeg108.6 KB · Views: 34

C75E1183-0B63-47DA-9E4C-E5E2D9DE3586.jpeg108.6 KB · Views: 34 -

12F61802-0B74-425D-9B50-9597DD59CBB2.jpeg65 KB · Views: 29

12F61802-0B74-425D-9B50-9597DD59CBB2.jpeg65 KB · Views: 29 -

58954215-D3B8-4D63-A67D-22B69919556D.jpeg86.6 KB · Views: 33

58954215-D3B8-4D63-A67D-22B69919556D.jpeg86.6 KB · Views: 33 -

5ECAA698-2048-450C-8499-02B373689AF8.jpeg75.7 KB · Views: 35

5ECAA698-2048-450C-8499-02B373689AF8.jpeg75.7 KB · Views: 35 -

8224FA15-14D0-4A40-95C6-C66D4408D52F.jpeg69.9 KB · Views: 36

8224FA15-14D0-4A40-95C6-C66D4408D52F.jpeg69.9 KB · Views: 36 -

941BA7B0-A1E7-4985-9D7F-D45524C5CA08.jpeg75.3 KB · Views: 36

941BA7B0-A1E7-4985-9D7F-D45524C5CA08.jpeg75.3 KB · Views: 36

![20220327_145338[1].jpg 20220327_145338[1].jpg](https://www.hobby-machinist.com/data/attachments/359/359244-053ea703b5d2f2d7ab50558f9d4372cd.jpg)