Hopefully this is the correct forum for such a post.

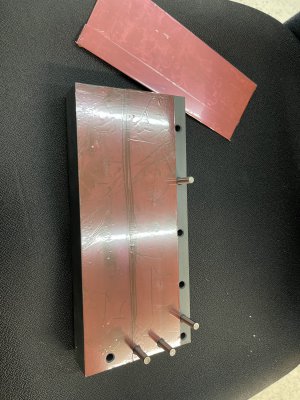

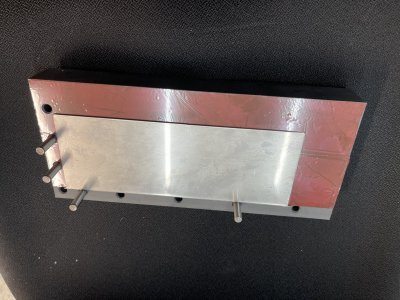

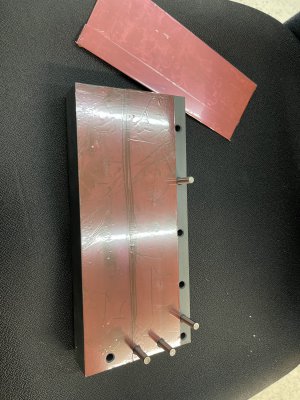

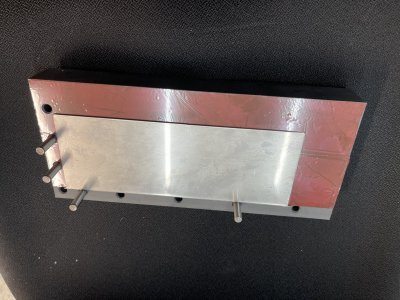

I have about 100 small .053 thick stainless steel coupons that are 2.75x8.5" in dimension. I want to engrave my logo into them but have been concerned with how to hold them in a vice. I build this small acetal fixture to hopefully be able to hold these as well as other thin objects with superglue (2P-10) and powdercoat tape between the fixture and part being cut. I haven't tried it out yet still mustering up the courage to fling a piece of stainless through my CNC panels (tho a .020 ball-nose engraver probably wont apply enough forces like a shellmill would "ask me how I know this"). Drilled/Reamed some 0.250 holes to accept dowel pins for consistent indexing. I'll send photos of the engraving once I do that.

I have about 100 small .053 thick stainless steel coupons that are 2.75x8.5" in dimension. I want to engrave my logo into them but have been concerned with how to hold them in a vice. I build this small acetal fixture to hopefully be able to hold these as well as other thin objects with superglue (2P-10) and powdercoat tape between the fixture and part being cut. I haven't tried it out yet still mustering up the courage to fling a piece of stainless through my CNC panels (tho a .020 ball-nose engraver probably wont apply enough forces like a shellmill would "ask me how I know this"). Drilled/Reamed some 0.250 holes to accept dowel pins for consistent indexing. I'll send photos of the engraving once I do that.