- Joined

- Oct 17, 2018

- Messages

- 966

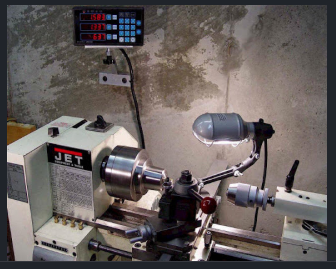

I'm finally getting around to mounting the DRO readouts for my lathe. All of the lathes I've used before had the DRO readouts over the headstock. I need to see the readout and the part being cut. This lathe doesn't really have a good place and the headstock cover needs room to lift off. I was going to put them on the cross slide cover I made, but that seems like it would get cutting oil and chips flung all over it. I've got cords to run as well. I have a wall behind the lathe, but the cords might drag. I was trying to figure out a way to mount the readouts so the cords were not running on the table, but were tucked up by the machine. I've looked in the 'net and can't really find anything specific about mounting the readouts, just the read heads. So, I thought I would ask and see what others did.

Idea #1: Mount behind chuck. Thought I'd make some sort of clamp to attach it to the bracket that holds the cover.

Idea #2: mount on the front of the headstock. I'd have to run the wires under the bed, so not sure I like this.

Idea #3: mount on the cover I made for the cross slide. Doesn't seem very sturdy; the cover is only held on at one end. However, it's not too bad. I'm concerned with vibrations.

Idea #4: mount on wall behind the lathe. I have a little shelf I could attach them to.

Idea #5: mount the heads on some sort of mounting bracket that attaches to the cover. There is a hole I could use.

Thoughts? Thanks!

Idea #1: Mount behind chuck. Thought I'd make some sort of clamp to attach it to the bracket that holds the cover.

Idea #2: mount on the front of the headstock. I'd have to run the wires under the bed, so not sure I like this.

Idea #3: mount on the cover I made for the cross slide. Doesn't seem very sturdy; the cover is only held on at one end. However, it's not too bad. I'm concerned with vibrations.

Idea #4: mount on wall behind the lathe. I have a little shelf I could attach them to.

Idea #5: mount the heads on some sort of mounting bracket that attaches to the cover. There is a hole I could use.

Thoughts? Thanks!