I'd like to get my new lube cube working. This weekend i opened it up and realized i've got some basic knowledge gaps. I called SST when i ordered it and spoke to them (very nice, helpful, and i appreciated they took the time). Ill call them back if i cant figure it out here. They made a custom package for me with two lube cubes and two 120v solenoids so that i could, in theory, turn on either single sprayer at once. But..... once i got to looking at the thing it appears that two solenoids will not make this work.

From what i see pressurized air enters the reservoir on one end; i assume this regulated air feed end is where a single solenoid is intended to be mounted. On the output end of the reservoir are FOUR outputs: two from the top of the tank (air) and two have leads to the bottom of the tank (fluid). A dual line runs to the lube cube sprayer for each sprayer. It appears to me air in the reservoir both passes through to the sprayer, and pressurizes the tank, forcing fluid to the sprayer. In the sprayer head these are mixed and expelled. I assume the design required separate fluid and air lines before the head, otherwise it would be a single line. If i mount a solenoid on just one of each of the dual lines as they exit the tank air pressure will still force air or lube (whichever i don't put the solenoid on) no matter what right? Im not missing something am i? So it seems like with two solenoids there is no way to make each sprayer head independently operable. Right? how could i do what i want? four solenoids? seems silly.

If anyone has a nice neat job of a similar lube cube setup installed id appreciate seeing that.

Also this is my first solenoid adventure. It looks like a simple device, but they stay energized to stay open at the designed voltage right? so switches need to be single pole 120v. Would it be better to run a relay? or just use line voltage to the controls and back to the solenoid? Im tryign to learn the machine control stuff too.

From what i see pressurized air enters the reservoir on one end; i assume this regulated air feed end is where a single solenoid is intended to be mounted. On the output end of the reservoir are FOUR outputs: two from the top of the tank (air) and two have leads to the bottom of the tank (fluid). A dual line runs to the lube cube sprayer for each sprayer. It appears to me air in the reservoir both passes through to the sprayer, and pressurizes the tank, forcing fluid to the sprayer. In the sprayer head these are mixed and expelled. I assume the design required separate fluid and air lines before the head, otherwise it would be a single line. If i mount a solenoid on just one of each of the dual lines as they exit the tank air pressure will still force air or lube (whichever i don't put the solenoid on) no matter what right? Im not missing something am i? So it seems like with two solenoids there is no way to make each sprayer head independently operable. Right? how could i do what i want? four solenoids? seems silly.

If anyone has a nice neat job of a similar lube cube setup installed id appreciate seeing that.

Also this is my first solenoid adventure. It looks like a simple device, but they stay energized to stay open at the designed voltage right? so switches need to be single pole 120v. Would it be better to run a relay? or just use line voltage to the controls and back to the solenoid? Im tryign to learn the machine control stuff too.

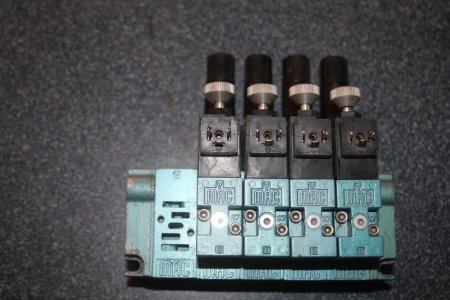

I know I have a lot of hose for them , but may have more banks etc . If you can use them , they're yours for shipping only as they were headed out to their burial grounds anyways .

I know I have a lot of hose for them , but may have more banks etc . If you can use them , they're yours for shipping only as they were headed out to their burial grounds anyways .