- Joined

- Aug 22, 2012

- Messages

- 4,264

well, not both halves.

I cleaned the lathe the other day and made some adjustments oiled etc.

When running the lead screw from the tail stock to the head stock with the half nuts closed as if threading I noticed the carriage stopped moving about half way along. It looked as if the half nuts had opened a little and let them lose their grip.

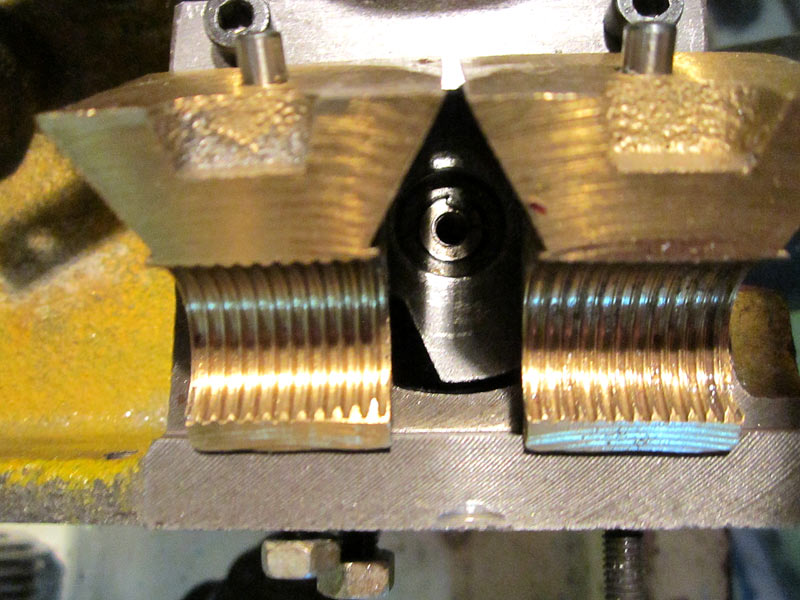

I stripped it all down to check what was happening and found one half was ok but the other half had a lot of wear.

The difference in the wear is very apparent here.

I believe these are made with unobtanium as the price is $50+ with a 16 week delivery schedule or 4 weeks if I pay another $60 for expedited air mail. Ordering from the states is no better.

If I hold the worn half nut to the lead screw it seems a good fit so probably will still work if everything is adjusted to zero play and they clamp up tight.

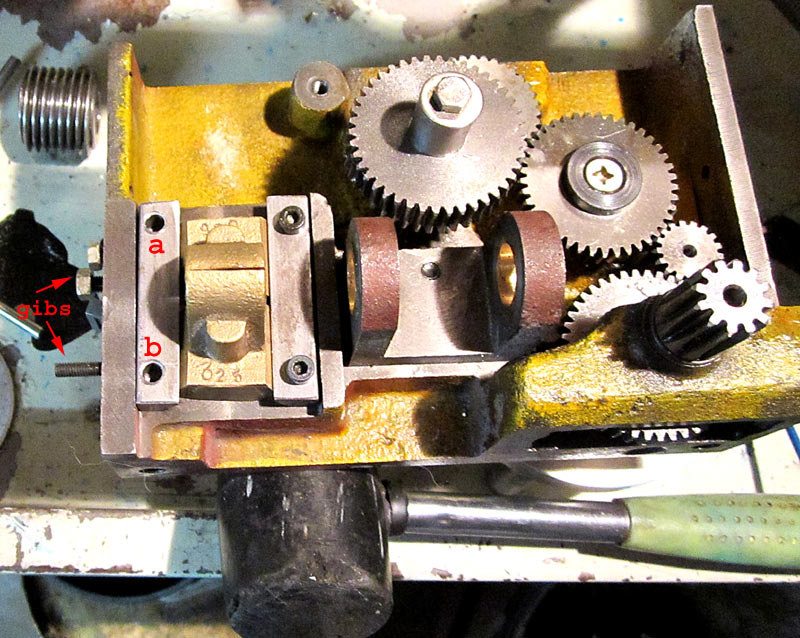

The two gib screws are I assume supposed to move the dovetail section to take up play, they cant because the holes "a" and "b" do not allow sufficient movement to do this.

Should I just bore them out to a larger diameter (easy) or machine then to a slot (harder) to get sufficient adjustment?

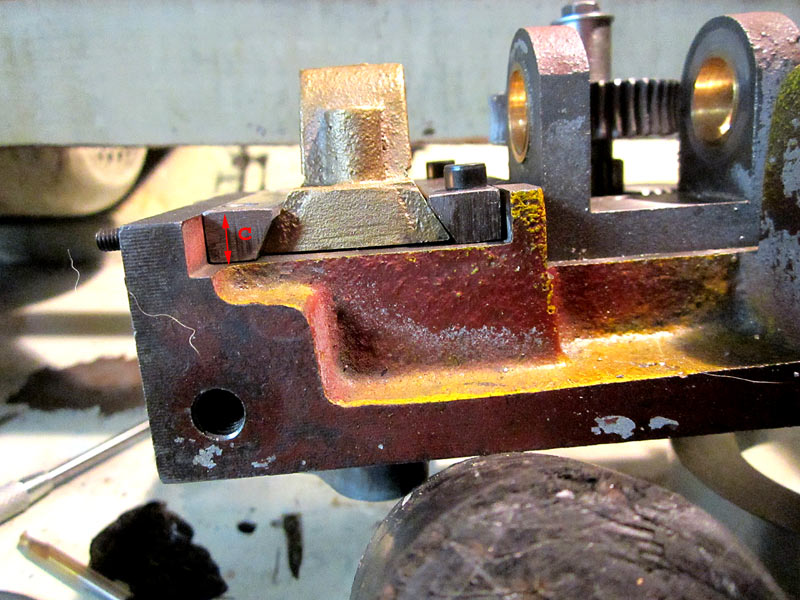

Or should I thin down "c" so the dovetail strip can take up the play as its bolted down. Easy but I think difficult to get exact and leaves no adjustment for wear.

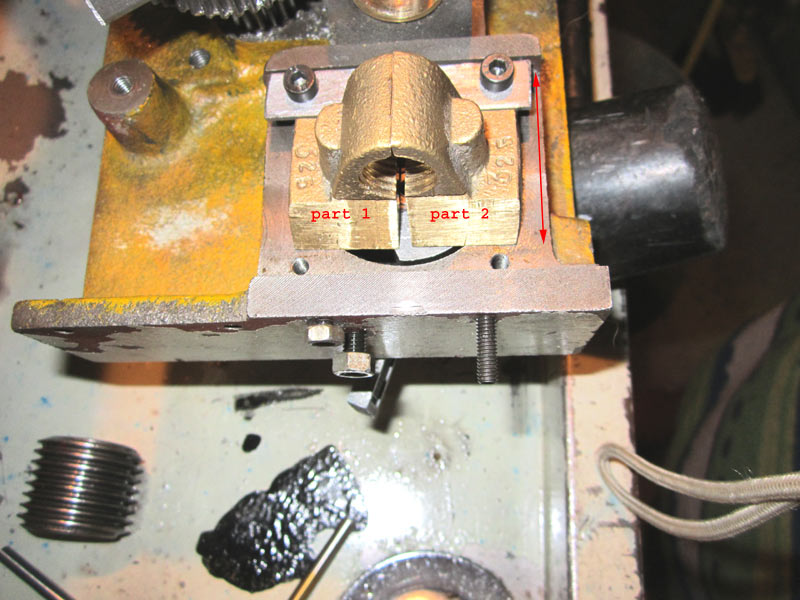

There is also I think a bit of a problem with the width of the two parts

With them pushed into the dovetail as shown part one is approx 5+ thou wider (in the arrowed dimension) than part two so even if the dovetails are adjusted to remove play it will only work on one of the half nuts.

The 5+ thou is guess work as I can figure out how to measure it exactly.

Would I be correct in thinking I have to remove this extra material so the are both exactly the same width?

I know the two half nuts are touching here but I didnt check if they touch when the lead screw is between them.

If they do then should I again remove some material so they dont touch when clamped up tight.

Last question (honest, for now)

The dimple for the detant is I believe in the wrong place (no pics but there are two overlapping dimples) because the handle to operate the half nuts can be closed a bit more but then springs back to one of the dimples.

Any ideas how to fill these dimples so I can drill a new one?

I cleaned the lathe the other day and made some adjustments oiled etc.

When running the lead screw from the tail stock to the head stock with the half nuts closed as if threading I noticed the carriage stopped moving about half way along. It looked as if the half nuts had opened a little and let them lose their grip.

I stripped it all down to check what was happening and found one half was ok but the other half had a lot of wear.

The difference in the wear is very apparent here.

I believe these are made with unobtanium as the price is $50+ with a 16 week delivery schedule or 4 weeks if I pay another $60 for expedited air mail. Ordering from the states is no better.

If I hold the worn half nut to the lead screw it seems a good fit so probably will still work if everything is adjusted to zero play and they clamp up tight.

The two gib screws are I assume supposed to move the dovetail section to take up play, they cant because the holes "a" and "b" do not allow sufficient movement to do this.

Should I just bore them out to a larger diameter (easy) or machine then to a slot (harder) to get sufficient adjustment?

Or should I thin down "c" so the dovetail strip can take up the play as its bolted down. Easy but I think difficult to get exact and leaves no adjustment for wear.

There is also I think a bit of a problem with the width of the two parts

With them pushed into the dovetail as shown part one is approx 5+ thou wider (in the arrowed dimension) than part two so even if the dovetails are adjusted to remove play it will only work on one of the half nuts.

The 5+ thou is guess work as I can figure out how to measure it exactly.

Would I be correct in thinking I have to remove this extra material so the are both exactly the same width?

I know the two half nuts are touching here but I didnt check if they touch when the lead screw is between them.

If they do then should I again remove some material so they dont touch when clamped up tight.

Last question (honest, for now)

The dimple for the detant is I believe in the wrong place (no pics but there are two overlapping dimples) because the handle to operate the half nuts can be closed a bit more but then springs back to one of the dimples.

Any ideas how to fill these dimples so I can drill a new one?