- Joined

- Dec 18, 2019

- Messages

- 7,428

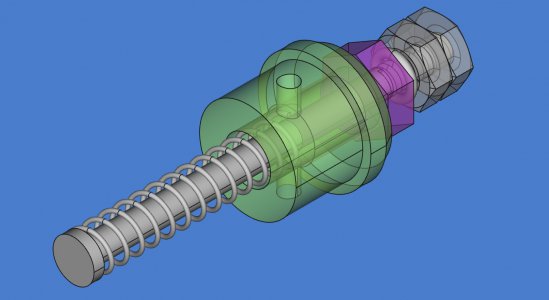

Been toying with this the past day or two. An SSG is used to reduce hammer bounce in air guns. This can in turn reduce gas or air usage and usually results in lower extreme spread of velocity in shot strings. Not my invention, but merely my bumbling version, machining nearly everything from raw materials.

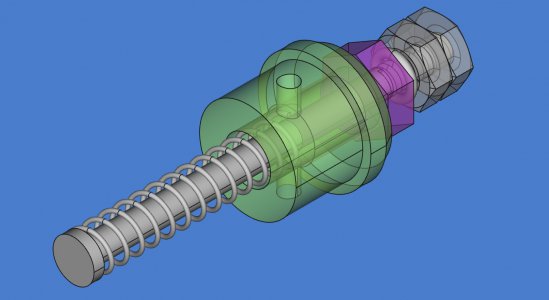

Design concept

Made a couple of changes - some due to my screw ups, some because I thought the ordinary nuts were ugly. So I knurled some stainless instead.

The report is shorter using the SSG, indicating lower gas consumption. (Shorter dwell time.) The 2240 is a CO2 single shot air gun. Bought it on sale new for $45. The rod is adjusted so it does not touch the hammer when at the hammer's maximum distance. Single pointed the threads, save for the 3/8-24 cap. Used a tap there. Should have single pointed them, as the tap ran large. Had to remake the adjuster screw (3/80-24 threads) because the tap size ran large. The adjuster screw was made from hex stock, turned to 3/8, single pointed, then drilled and reamed to 3/16" Then the bottom was bored to 0.280" diameter, 0.250" deep for the spring. Was a fun little project on the lathe.

Might make a different version of this, maybe something to cover up the nuts. They could be somewhat of a hazard to someone not paying attention. This is when the air gun is cocked.

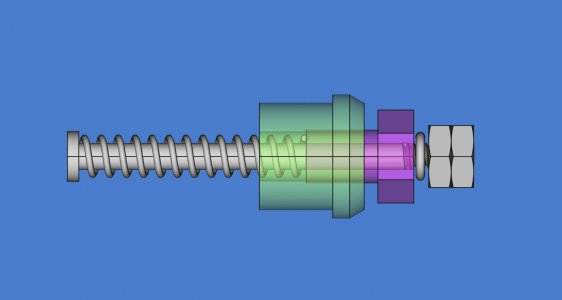

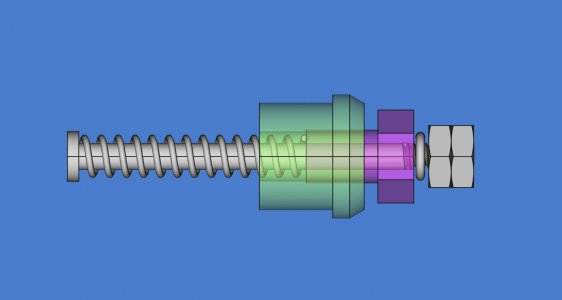

Design concept

Made a couple of changes - some due to my screw ups, some because I thought the ordinary nuts were ugly. So I knurled some stainless instead.

The report is shorter using the SSG, indicating lower gas consumption. (Shorter dwell time.) The 2240 is a CO2 single shot air gun. Bought it on sale new for $45. The rod is adjusted so it does not touch the hammer when at the hammer's maximum distance. Single pointed the threads, save for the 3/8-24 cap. Used a tap there. Should have single pointed them, as the tap ran large. Had to remake the adjuster screw (3/80-24 threads) because the tap size ran large. The adjuster screw was made from hex stock, turned to 3/8, single pointed, then drilled and reamed to 3/16" Then the bottom was bored to 0.280" diameter, 0.250" deep for the spring. Was a fun little project on the lathe.

Might make a different version of this, maybe something to cover up the nuts. They could be somewhat of a hazard to someone not paying attention. This is when the air gun is cocked.