-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stones to polish ways in my lathe?

- Thread starter akschu

- Start date

- Joined

- Oct 29, 2014

- Messages

- 360

As has been mentioned above, stoning your lathes ways would generally be frowned upon. Can you explain why you want to do so? I think you might be asking about precision ground flat stones, depends on what you are trying to accomplishCan anyone link me to some reasonably priced stones? I can't seem to figure out what I need and everything seems to be for knife sharpening. Amazon is okay, though I avoid them these days. Ebay is good or MSC.

Thanks!!!

- Joined

- Apr 23, 2018

- Messages

- 6,886

If you have nicks or damage to the ways that bring a raised spot on the surface, stoning them flat is a reasonable thing to do. A cheap India deburring stone wetted with mineral spirits and a careful approach is an acceptable remedy in my book.

- Joined

- Nov 25, 2015

- Messages

- 9,779

yep, stoning the high spots is ok, and valid.

Stoning to solve a straightness problem... NOT VALID!!!!!

Stoning to solve a straightness problem... NOT VALID!!!!!

- Joined

- Mar 26, 2018

- Messages

- 8,666

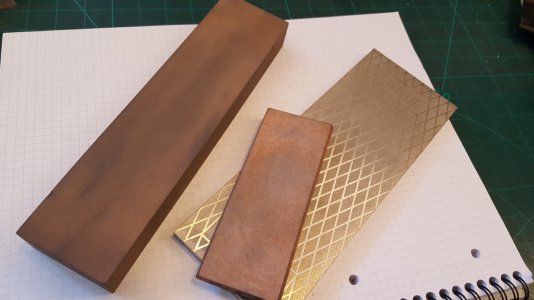

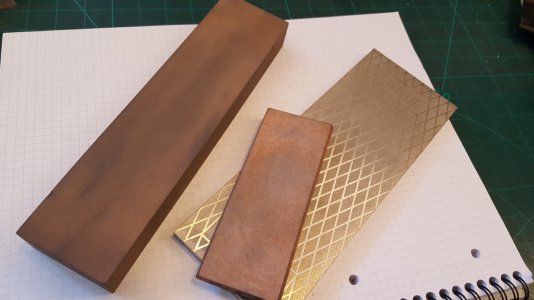

Youcan use precision ground stones to remove the high spots.

I just took a pic of my cross slide. You can see the shiny spots.

They will only remove high spots without scratching!

They are expensive unless you have a surface grinder and a CBN or Diamond wheel.

I just took a pic of my cross slide. You can see the shiny spots.

They will only remove high spots without scratching!

They are expensive unless you have a surface grinder and a CBN or Diamond wheel.

Attachments

- Joined

- Jul 10, 2013

- Messages

- 1,212

This may be a scraping issue. Why do you want to take a stone to the ways of your lathe?

- Joined

- May 27, 2016

- Messages

- 3,479

I have a 8" x 3" 3/8" thick steel diamond hone.

#300 on one side, and #1000 on the other side. Lacking the Renzetti resource to surface grind two flat stones, I simply rubbed the medium India stone ex-woodwork chisel sharpener on #300 side. It gets so flat that it skids on other flat stuff without cutting. Rubbing two stones together that have each seen the diamond might be a partial version of the 3-plate method, but anyway, one slides over the other almost like on an air layer.

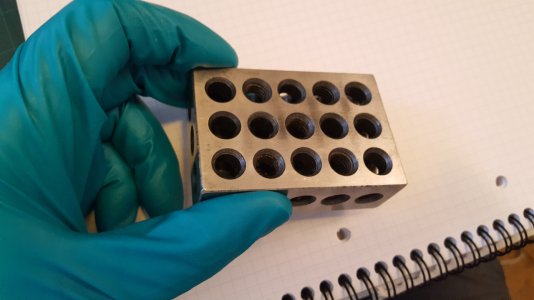

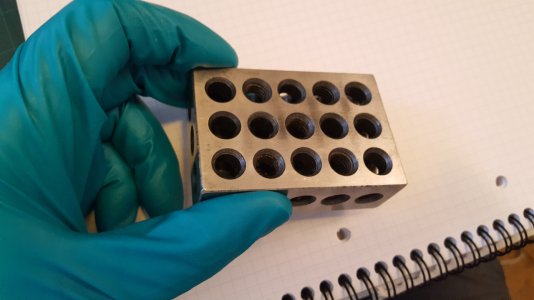

Basically, there are only two surfaces that can slide over each other. They are both on a single shared plane, or they are each on a piece of the same sphere. If one is loaded with diamonds, it will be the winner, Rubbing two stones treated this way, they skid over each other without cutting. I tried it on a new 123-block, and all it did was start mirror polishing to reveal the real accuracy of the surface grinding underneath.

With a stone like this, known to be flat enough, and used right, you cannot hurt a lathe way, except for knocking down dings. If there are remaining oil-retention scrape flaking marks, it just makes them look beautiful! Do it à recette @pontiac428. Even a small wedge-type slip stone, made and kept really flat, and used in the proper way, will do nicely. After all, a stone is the final thing used on a precision beautiful scraped surface. Don't be afraid of it!

DO NOT harsh grind lathe ways with stones! That is not the same thing as "stoning".

I guess @Janderso may not approve the cheapskate approach, and we would not dare darken Robin's door with this stuff!

#300 on one side, and #1000 on the other side. Lacking the Renzetti resource to surface grind two flat stones, I simply rubbed the medium India stone ex-woodwork chisel sharpener on #300 side. It gets so flat that it skids on other flat stuff without cutting. Rubbing two stones together that have each seen the diamond might be a partial version of the 3-plate method, but anyway, one slides over the other almost like on an air layer.

Basically, there are only two surfaces that can slide over each other. They are both on a single shared plane, or they are each on a piece of the same sphere. If one is loaded with diamonds, it will be the winner, Rubbing two stones treated this way, they skid over each other without cutting. I tried it on a new 123-block, and all it did was start mirror polishing to reveal the real accuracy of the surface grinding underneath.

With a stone like this, known to be flat enough, and used right, you cannot hurt a lathe way, except for knocking down dings. If there are remaining oil-retention scrape flaking marks, it just makes them look beautiful! Do it à recette @pontiac428. Even a small wedge-type slip stone, made and kept really flat, and used in the proper way, will do nicely. After all, a stone is the final thing used on a precision beautiful scraped surface. Don't be afraid of it!

DO NOT harsh grind lathe ways with stones! That is not the same thing as "stoning".

I guess @Janderso may not approve the cheapskate approach, and we would not dare darken Robin's door with this stuff!

Last edited: