- Joined

- Jul 22, 2022

- Messages

- 138

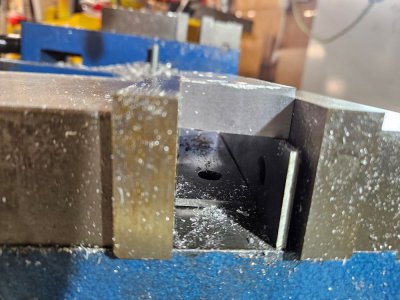

have a atlas clausing 4803 12x36 inch lathe, finally starting to make the adapter parts to mount the scales, todays project was the spacer for the cross slide, had 2 different setups for it this was to notch for the bulge that the compound makes in the cross slide, 4" diameter notch used a 4 inch diameter shell mill. second setup was to cut the 5 degree draft angle onto the aluminum spacer, i apparantly did not get a picture of this setup but basically just turned the angle table sideways and set it at 5 degrees with a ball ended jack holding the far end. later i will drill my 4 1/4-20 pass throughs in it and then drill and tap the cross slide to match, .... wish i was farther along this journey lol