I’m new to machining but I’ve already got some jobs to do with the old Comet milling machine we just got at our shop. A guy who owned a machine shop two blocks down sold his business and we got the Comet, a surface grinder, and a bunch of end mills.

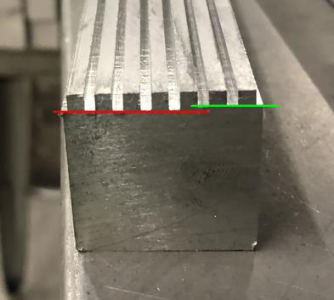

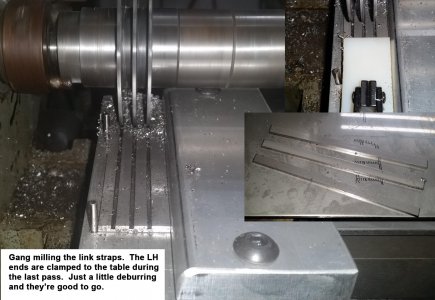

We’ve got everything set up and I just spent today cutting the 6061 aluminum, 1.25” solid tubing with 5, 3” medium slitting saws stacked 0.125” apart.

The task at hand is making aluminum rungs for a ladder we’re fabricating. There are 20 pieces at 18” and I have to make a pass, flip the work, and make a second pass to cover the entire side of the rung. They have to be 0.125” deep, on all 4 sides. I’ve got the mill in low gear at about 200rpm, compressed air to blow the chips out (no coolant yet), and tap oil on a paint brush.

I did 10 sides today and towards the end of all of them I would get screeching, and sometimes it would almost stall and then cut every 0.020”.

Is the noise from lack of coolant, 0.125” depth of cut, or normal?

We’ve got everything set up and I just spent today cutting the 6061 aluminum, 1.25” solid tubing with 5, 3” medium slitting saws stacked 0.125” apart.

The task at hand is making aluminum rungs for a ladder we’re fabricating. There are 20 pieces at 18” and I have to make a pass, flip the work, and make a second pass to cover the entire side of the rung. They have to be 0.125” deep, on all 4 sides. I’ve got the mill in low gear at about 200rpm, compressed air to blow the chips out (no coolant yet), and tap oil on a paint brush.

I did 10 sides today and towards the end of all of them I would get screeching, and sometimes it would almost stall and then cut every 0.020”.

Is the noise from lack of coolant, 0.125” depth of cut, or normal?