- Joined

- Aug 26, 2020

- Messages

- 12

Hi all,

I'm still very new to this, so while I tried to read everything I could, I'm sorry if I missed some pertinent information.

About a week and a half ago, I received the 8-Direction Upgrade for my 5400 (actually a Lathe Vertical Milling Column, 15" Column Upgrade [added later], and 12" XY base). It has a DRO hand wheel on each axis. I'm still using the lathe headstock/motor on the mill.

I think I've managed to square up everything, but the headstock's rotation is off.

My tools are:

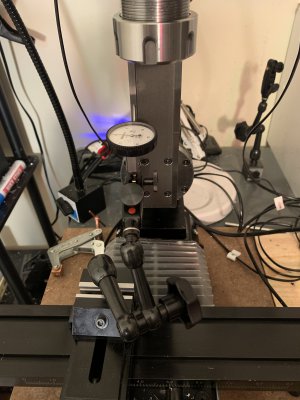

A Mitutoyo DTI.

A Noga NF1022.

A Beall ER-32 collet chuck and a Techniks 5/16th collet, purchased new, for holding the Noga.

A Starrett No. 20 square, from ebay. I validated this while squaring up the mill; once the column was dead square, I moved the square to the other side, and it still read dead square.

Here's what I did:

I measured the flatness of the bed with a DTI. Left-to-right differed by about 0.5 thou over roughly 4 inches, front-to-back, about 7 thou over roughly 3 inches.

I squared the column around the z axis with a DI (I repeated this step several times over the course of the procedure, as tapping the column put it out of square).

I then squared the column over around the x and y axes by first holding the square against the side and tapping until light came through evenly through the gap. Then, I swept across the square with the DTI and tapped the column until the needle no longer moved. For the y axis, I also made sure it read square from the other side.

Finally, I checked the orientation of the headstock by reading the height of the left and right sides of the mill table. I usually used the DI here to avoid having to push the DTI needle across the "ledges" from the T slots and edge of table (this is also why I used it for squaring around the z axis, as described above). Initially, the left side reads 15 thou lower than the right, over 9 inches. If I put counter-clockwise pressure on the headstock while tightening it, the difference is lower, but still at least 5 thou.

Am I doing something wrong, or is there something wrong with my equipment?

I wonder if I damaged something while installing the 15" Column Upgrade - I'm still having trouble with the z axis hand wheel; given consistent hand wheel movement, occasionally the headstock will stop or slip. I've been working under the assumption I just have to get the gib and hand wheel backlash adjusted properly, and have been making attempts for several weeks. The orientation of the saddle does appear to change with the gib adjustment, but doesn't have a major effect on the headstock orientation.

Thanks in advance,

Elliot

I'm still very new to this, so while I tried to read everything I could, I'm sorry if I missed some pertinent information.

About a week and a half ago, I received the 8-Direction Upgrade for my 5400 (actually a Lathe Vertical Milling Column, 15" Column Upgrade [added later], and 12" XY base). It has a DRO hand wheel on each axis. I'm still using the lathe headstock/motor on the mill.

I think I've managed to square up everything, but the headstock's rotation is off.

My tools are:

A Mitutoyo DTI.

A Noga NF1022.

A Beall ER-32 collet chuck and a Techniks 5/16th collet, purchased new, for holding the Noga.

A Starrett No. 20 square, from ebay. I validated this while squaring up the mill; once the column was dead square, I moved the square to the other side, and it still read dead square.

Here's what I did:

I measured the flatness of the bed with a DTI. Left-to-right differed by about 0.5 thou over roughly 4 inches, front-to-back, about 7 thou over roughly 3 inches.

I squared the column around the z axis with a DI (I repeated this step several times over the course of the procedure, as tapping the column put it out of square).

I then squared the column over around the x and y axes by first holding the square against the side and tapping until light came through evenly through the gap. Then, I swept across the square with the DTI and tapped the column until the needle no longer moved. For the y axis, I also made sure it read square from the other side.

Finally, I checked the orientation of the headstock by reading the height of the left and right sides of the mill table. I usually used the DI here to avoid having to push the DTI needle across the "ledges" from the T slots and edge of table (this is also why I used it for squaring around the z axis, as described above). Initially, the left side reads 15 thou lower than the right, over 9 inches. If I put counter-clockwise pressure on the headstock while tightening it, the difference is lower, but still at least 5 thou.

Am I doing something wrong, or is there something wrong with my equipment?

I wonder if I damaged something while installing the 15" Column Upgrade - I'm still having trouble with the z axis hand wheel; given consistent hand wheel movement, occasionally the headstock will stop or slip. I've been working under the assumption I just have to get the gib and hand wheel backlash adjusted properly, and have been making attempts for several weeks. The orientation of the saddle does appear to change with the gib adjustment, but doesn't have a major effect on the headstock orientation.

Thanks in advance,

Elliot